What are rubber D-ring seals? Learn their functionalities, industry uses, installation methods, lifespan factors, benefits, and how they differ from O-ring seals.

Pipe gaskets provide reliable sealing between pipe joints and flange connections to prevent fluid, gas, and pressure leakage in piping systems. They function as critical sealing components that absorb surface irregularities, support pressure containment, and reduce vibration across connected pipe sections.

Pipe gaskets offer dependable performance across different temperatures, pressures, and media types, depending on material selection.

Rubber Xpert Inc. manufactures and supplies custom pipe gaskets with precision cutting, certified materials, and bulk production capabilities for industrial and pipeline applications.

Buy pipe gaskets in bulk directly from a manufacturer equipped for certified materials, consistent quality control, and precision-cut custom dimensions. Rubber Xperts Inc. supports OEM requirements with competitive pricing, fast turnaround, and reliable bulk supply for plumbing, pipeline, and industrial sealing systems.

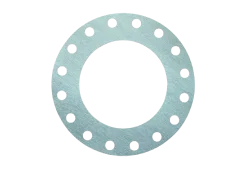

Flat pipe gaskets are engineered for general-purpose sealing in pipe joints requiring uniform load distribution, durability, and pressure stability. They deliver reliable sealing performance where consistent surface contact and controlled compression are critical.

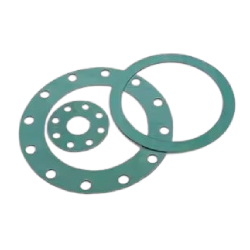

Ring-type pipe gaskets are engineered for flange joints requiring focused sealing stress and improved pressure handling. They perform reliably where higher internal pressure and tighter sealing control are required.

Full-face pipe gaskets are engineered to cover the entire flange surface, including bolt holes, providing added protection and load distribution. They deliver consistent sealing where flange alignment and vibration are concerns.

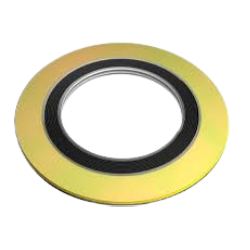

Spiral wound pipe gaskets are engineered for high-pressure and high-temperature sealing applications requiring resilience and recovery. They perform reliably in environments with thermal cycling and fluctuating pressure.

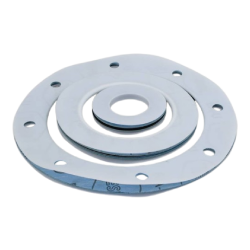

PTFE pipe gaskets are engineered for chemically aggressive environments requiring inertness and high-temperature stability. They deliver dependable sealing where corrosion and contamination must be avoided.

Rubber pipe gaskets are engineered for flexible sealing and vibration absorption in low- to medium-pressure piping. They provide effective sealing where movement and surface variation are present.

Custom pipe gaskets are engineered for application-specific piping systems requiring precise fit, material compatibility, and controlled tolerances. They deliver optimized sealing where standard gasket sizes are insufficient.

Rubber Xperts Inc. uses certified gasket materials and engineering-grade manufacturing processes to deliver precision-crafted pipe gaskets designed for durability, sealing accuracy, and consistent performance across piping systems.

Every gasket is produced under strict quality controls to ensure reliability in pressure, temperature, and fluid-handling environments.

Reasons to buy pipe gaskets from Rubber Xperts Inc include:

We review the operating pressure, temperature range, fluid media, pipe size, flange standard, and tolerance limits to define sealing performance targets.

Our engineers create detailed CAD models covering gasket geometry, bolt-hole layout, thickness, and sealing surfaces. All models are aligned to applicable standards.

We select materials such as EPDM, NBR, PTFE, graphite, or composite fibers based on chemical compatibility, pressure class, and thermal limits.

We produce the prototype gaskets for fit-up checks, compression behavior, and dimensional verification before production approval.

Your approved designs move into CNC cutting, die-cutting, or forming processes to maintain consistent tolerances at scale.

Each batch of pipe gasket undergoes dimensional inspection, material verification, and compliance checks against specified tolerances and standards.

The finished pipe gaskets are packaged for protection, labeled for traceability, and delivered through reliable logistics channels.

Pipe gaskets are sealing components installed between pipe joints or flanged connections to create a leak-tight seal. Their primary function is to prevent the escape of liquids or gases while maintaining pressure integrity across connected piping sections.

Pipe gaskets provide effective sealing by compensating for surface irregularities, supporting pressure containment, and absorbing vibration. Depending on material choice, pipe gaskets also offer temperature resistance, chemical compatibility, and insulation properties.

Industries like plumbing, pipelines, HVAC, oil and gas, and industrial fluid systems rely on pipe gaskes because they ensure safe, efficient, and long-term operation of piping networks.

Flat pipe gaskets are simple, full-contact sealing components placed between pipe flanges. They provide uniform load distribution and dependable sealing. Flat pipe gaskets are best for water lines, HVAC, and low- to medium-pressure piping. Selection should consider material compatibility and flange surface finish.

Ring-type pipe gaskets seal only the raised face area of flanges, concentrating sealing stress. They offer improved pressure handling, and are best for oil & gas and industrial process piping. Correct sizing and flange standard matching are critical when choosing ring-type pipe gaskets.

Full-face pipe gaskets cover the entire flange surface, including bolt holes, offering added protection and vibration control. They are best for low-pressure systems and water treatment, but are not ideal for high-pressure or high-temperature services.

Spiral wound pipe gaskets combine metal windings with soft fillers for resilience. They handle high pressure and temperature with excellent recovery. Spiral wound pipe gaskets are best for refineries, power plants, and chemical processing. Ehowever, they require controlled bolt load and proper flange finish.

PTFE pipe gaskets provide chemically inert, non-contaminating sealing. They perform across extreme temperatures. These pipes are perfect for chemical, food-grade, and corrosive services, but cold flow must be managed with correct compression.

Rubber pipe gaskets offer flexible sealing and vibration damping. They suit low- to medium-pressure systems. Rubber pipe gaskets are best for plumbing and HVAC, but the material choice must match fluid and temperature exposure.

Custom pipe gaskets are manufactured to exact dimensions and specifications. They ensure optimal sealing where standard sizes fail. Custom pipe gaskets are best for OEM and specialized piping. Accurate tolerances and application data are essential.

The materials used to manufacture pipe gaskets include:

| Material | Operating Temperature | Compression Set | Chemical Resistance | Cost | Best For |

|---|---|---|---|---|---|

| EPDM | −40°C to +150°C | Low | Excellent (Water, Steam, Mild Chemicals) | Low | Water Lines, HVAC, Outdoor Piping |

| Nitrile (NBR) | −30°C to +120°C | Moderate | Excellent (Oils, Fuels, Hydrocarbons) | Low–Medium | Oil & Gas, Fuel Pipelines |

| Neoprene | −35°C to +120°C | Moderate | Good (Water, Mild Oils) | Medium | General Industrial Piping |

| PTFE (Teflon) | −200°C to +260°C | Low (Creep-Prone) | Excellent (Near-Universal) | Medium–High | Chemical, Food-Grade, Corrosive Services |

| Graphite | −200°C to +450°C | Very Low | Excellent (High-Temp, Aggressive Media) | High | High-Temperature, High-Pressure Pipelines |

| Fiber / Composite | −40°C to +200°C | Low–Moderate | Good (Oils, Steam) | Medium | Industrial Flange Sealing |

To choose the right pipe gasket for your needs, match sealing performance to operating conditions, safety requirements, and compliance standards to prevent leaks and premature failure.

Here are tips to choose the right pipe gasket for your needs:

Pipe gaskets are essential sealing components across multiple industries where fluid containment, pressure integrity, and system reliability are necessary. Their role varies by application, but the goal remains the same: prevent leaks and maintain safe pipe connections.

Industries where pipe gaskets are commonly used are:

Pipe gaskets seal joints in water supply and drainage lines. They ensure leak prevention, pressure stability, and long service life in residential and commercial plumbing.

In oil and gas pipelines, pipe gaskets provide secure sealing under high pressure and exposure to hydrocarbons. It supports safe transport and reducing the risk of leakage.

Pipe gaskets are used to seal piping that carries corrosive or reactive chemicals, delivering chemical compatibility and maintaining containment under elevated temperatures.

In HVAC and utility systems, pipe gaskets help maintain airtight and watertight joints. They improve system efficiency and minimizing vibration and energy loss.

Pipe gaskets support sealing in steam, cooling, and process piping. They handle high temperatures and pressure fluctuations critical to continuous power plant operation.

Pipe gaskets are used in pumps, valves, and transfer lines to ensure consistent fluid containment, reduce downtime, and protect equipment from leakage-related damage.

The key features and benefits of pipe gaskets include:

Provides reliable sealing across pipe joints to maintain pressure integrity and prevent fluid or gas loss.

Supports service temperatures from −40°C up to +450°C+ depending on material selection.

Designed to withstand low to high internal pressures when matched with the correct gasket type and flange load.

Available in materials resistant to water, oils, fuels, steam, and aggressive chemicals.

Manufactured to tight tolerances (typically ±0.1 mm) for consistent fit and uniform compression.

Delivers 5–10+ years of performance in properly specified industrial piping systems.

Here are step by step ways to install your pipe gaskets:

Clean flange faces thoroughly to remove dirt, oil, rust, and old gasket material. Clean surfaces ensure full gasket contact and reduce leak paths.

Align pipe flanges correctly before gasket placement. Proper alignment prevents uneven compression and gasket damage during tightening.

Position the pipe gasket centrally on the flange face, ensuring correct inner and outer diameter alignment and unobstructed bolt holes.

Tighten bolts gradually using a cross or star pattern. Apply torque in stages to achieve uniform compression and avoid overloading the gasket.

Slowly pressurize the system to operating conditions and inspect all joints for leakage using approved testing methods.

Recheck bolt torque after initial operation if required, and document installation parameters for maintenance reference.

Here are some frequently asked questions about our Pipe Gasket to help you find the answers you need:

The purpose of a pipe gasket is to prevents fluid or gas leakage while maintaining pressure integrity.

The best material for pipe gaskets depends on temperature, pressure, and fluid type. EPDM suits water, NBR suits oils, and PTFE suits chemicals.

Yes, pipe gaskets can handle high pressure when correctly selected. Spiral wound and graphite pipe gaskets are designed for high-pressure applications.

No, pipe gaskets are not reusable after removal. Once compressed, most pipe gaskets lose sealing effectiveness and should be replaced.

Properly specified pipe gaskets last 5–10 years, depending on operating conditions and material choice.

Yes, pipe gaskets need to meet compliance stands. Certain applications require compliance with FDA, ASTM, RoHS, or UL standards based on industry regulations.

"We recently purchased rubber gaskets from Rubber Xperts INC. and were thoroughly impressed with their service. The team demonstrated a high level of professionalism and ensured we received top-quality products. Their assistance throughout the process was invaluable, and they delivered everything on time. We highly recommend Rubber Xperts INC. for their exceptional quality and outstanding customer support."

"Our dairy organization has been partnering with Rubber Xperts INC. for a while now, and we frequently procure silicone dairy hoses from them. Their customer service and engineering team are outstanding, always ensuring we receive the best products and support. This partnership has been a great success, and we highly recommend Rubber Xperts INC. for their professionalism, quality, and reliability."

With years of experience in hydraulic and pneumatic systems, Rubber Xperts INC makes top-quality rubber products like rubber o-rings, rubber seals, rubber pipes, rubber extrusions, rubber gaskets, rubber mounts, rubber hoses, and more.

We cater to various industries such as construction, aviation, agriculture, and marine. Quality is our priority, ensuring you get the best possible experience and product.

Our team can locate any product for you such as Seals, O-Rings, Gaskets, Pipes, Hoses, and more. If you need help finding a very specific product, reach out to us by phone, email, or contact form. If it exists, we'll find it for you.

We're available Monday-Friday

from 8:00 AM to 6:00 PM EST,

and Saturday from 8:00 AM to 12:00 PM EST.

Top-notch customer support from us,

whether it's before or after your purchase.

Buy easily through our website or

just give us a call.

Customize your ordering and packing preferences with our flexible solutions tailored to your needs.