What are rubber D-ring seals? Learn their functionalities, industry uses, installation methods, lifespan factors, benefits, and how they differ from O-ring seals.

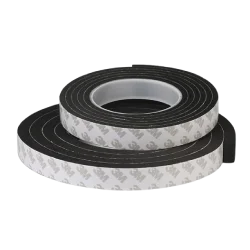

Foam gaskets offer flexible sealing, cushioning, and insulation for applications that require gap filling, vibration damping, and environmental protection. They function as compressible sealing components that conform to uneven surfaces, reducing noise and preventing air or moisture ingress.

Foam gaskets offer good flexibility, recovery, and durability across a wide temperature range, depending on material type. Rubber Xpert Inc. manufactures and supplies custom foam gaskets using precision cutting, multiple foam densities, and bulk production support.

Buy foam gaskets in bulk directly from a manufacturer equipped for certified materials, consistent quality control, and precision-cut custom dimensions. Rubber Xpert Inc. supports OEM programs with competitive pricing, fast turnaround, and reliable bulk supply for enclosure, HVAC, and industrial sealing applications.

Closed-cell foam gaskets are engineered for moisture-resistant sealing and compression recovery in applications requiring air- and water-tight performance. They deliver reliable sealing where environmental ingress and vibration are concerns.

Open-cell foam gaskets are engineered for cushioning, sound absorption, and low-load sealing where airflow and compressibility are needed. They perform well on irregular surfaces under light compression.

EPDM foam gaskets are engineered for outdoor durability and weather resistance. They deliver consistent sealing where UV, ozone, and moisture exposure are present.

Neoprene foam gaskets are engineered for balanced oil resistance, cushioning, and sealing performance. They perform reliably in general industrial environments.

Silicone foam gaskets are engineered for high-temperature and low-temperature sealing with excellent compression recovery. They deliver dependable performance where thermal extremes are present.

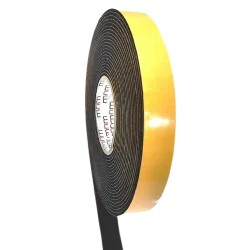

Adhesive-backed foam gaskets are engineered for fast installation and positional stability. They maintain foam sealing performance while simplifying assembly.

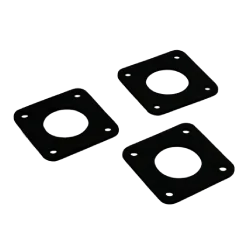

Custom foam gaskets are engineered to application-specific dimensions, densities, and performance needs. They deliver optimized sealing where standard profiles are insufficient.

Rubber Xperts Inc. uses certified foam materials and engineering-grade manufacturing processes to deliver precision-crafted foam gaskets designed for reliable sealing, cushioning, and insulation. Every gasket is produced under strict quality controls to ensure consistent performance across enclosure, HVAC, and industrial applications.

You buy foam gaskets from Rubber Xpert Inc. because of the following reasons:

Application needs are reviewed, including sealing purpose, compression range, environmental exposure, temperature limits, and dimensional tolerances.

Engineers create precise CAD models defining gasket profile, thickness, density, and compression targets to ensure proper fit and performance.

Foam type (EPDM, neoprene, silicone, PU, PE), cell structure, and density are selected based on sealing, cushioning, and durability requirements.

Prototype foam gaskets are produced to verify fit, compression recovery, and functional performance before production approval.

Approved designs move into CNC cutting, die-cutting, or kiss-cutting processes to maintain consistent tolerances at scale.

Each batch undergoes dimensional inspection, density checks, and compliance verification against specified requirements.

Finished foam gaskets are packaged to prevent deformation, labeled for traceability, and delivered through reliable logistics channels.

Foam gaskets are compressible sealing components made from cellular materials designed to fill gaps, absorb vibration, and block air, dust, and moisture. Their core function is to provide effective sealing and cushioning between mating surfaces, especially where surface irregularities exist.

Foam gaskets offer high flexibility, good compression recovery, and insulation properties, with performance varying by foam type and density. They also help with noise reduction and vibration damping while maintaining a lightweight profile.

Industries such as HVAC systems, electronics, automotive interiors, and industrial equipment rely on foam gaskets in enclosures. They deliver reliable sealing under low to moderate compression with easy installation.

Closed-cell foam gaskets are moisture-resistant seals with sealed cells that prevent air and water ingress. They provide good compression recovery and environmental sealing. Closed-cell foam gaskets are best for outdoor enclosures and HVAC panels. Higher density requires correct compression control.

Open-cell foam gaskets are highly compressible and breathable, designed for cushioning and sound absorption. They are best for electronics housings and acoustic applications, but are not suitable for water- or pressure-tight sealing.

EPDM foam gaskets offer excellent weather, UV, and ozone resistance with stable compression. They are best for outdoor enclosures and construction joints, but have limited resistance to oils and fuels.

Neoprene foam gaskets provide balanced cushioning, moderate oil resistance, and vibration damping. They are best for industrial panels and machinery covers, but not ideal for prolonged outdoor UV exposure without protection.

Silicone foam gaskets maintain flexibility across extreme temperatures and provide low compression set. They are best for electronics, lighting, and high/low-temperature enclosures, but its higher material cost than standard foams.

Adhesive-backed foam gaskets simplify installation and positioning. They are best for OEM assemblies and panels, but adhesive temperature limits must be considered.

Custom foam gaskets are engineered to exact shapes, densities, and thicknesses. They are best for specialized equipment and OEM designs. Accurate specifications are essential.

The materials used to manufacture foam gaskets include:

To choose the right foam gasket, you must match the foam type and density to your sealing, cushioning, and environmental requirements.

You can follow these tips to choose the right foam gasket for your needs:

Foam gaskets are widely used where flexible sealing, cushioning, and environmental protection are required, especially in low to moderate-pressure applications.

The places where foam gaskets are commonly used include:

Foam gaskets seal enclosure doors and panels to block dust and moisture, improve IP protection, and protect sensitive electrical components.

They are used in ducts, air handlers, and access panels to reduce air leakage, absorb vibration, and improve energy efficiency.

Foam gaskets help seal interior panels, HVAC modules, and trim components while reducing noise, vibration, and harshness.

They provide cushioning and sealing for housings, displays, and control panels, protecting against dust ingress and vibration.

Foam gaskets are applied in machinery covers and access points to provide flexible sealing and reduce mechanical vibration.

They are used for weatherstripping to block air, water, and dust while maintaining flexibility over repeated open–close cycles.

The key features and benefits of foam gaskets include:

Conforms easily to uneven or irregular surfaces, ensuring consistent contact and effective gap filling.

Operates from −60°C to +200°C depending on foam material (silicone, EPDM, neoprene).

Achieves reliable sealing under low to moderate clamping loads, reducing stress on assemblies.

Absorbs vibration and dampens sound, improving equipment performance and user comfort.

Closed-cell foams provide effective barriers against air, water, and particulate ingress.

Designed for 5–10 years of performance with proper material selection and compression control.

Steps to install foam gasket involve the following:

Clean the mating surfaces to remove dust, oil, moisture, and debris. Clean surfaces improve adhesion and sealing consistency.

Check component alignment before installation to ensure even compression and avoid stretching or twisting the foam gasket.

Position the foam gasket accurately along the sealing path. For adhesive-backed foam, apply light pressure gradually to ensure proper bonding.

Assemble the components and apply uniform compression. Avoid over-compressing to preserve foam recovery and sealing performance.

Inspect the sealed area for gaps, air leaks, or moisture ingress using the appropriate test method.

Confirm the gasket remains seated correctly after installation and initial operation, and recheck alignment if required.

Foam Gasket compression guidelines involve the following:

Foam gaskets typically perform best at 20–40% compression, depending on foam type and density.

Excessive compression can cause permanent deformation, loss of recovery, and reduced sealing effectiveness.

Lower-density foams require lighter clamping force, while higher-density foams tolerate higher loads.

Apply even fastening pressure across the sealing surface to prevent localized gaps or premature wear.

Foam gaskets rely on elastic recovery, so compression should stay within design limits for long-term performance.

Here are some frequently asked questions about our Foam Gaskets to help you find the answers you need:

Foam density determines compression force and recovery. Select a lower density for light loads and a higher density for tighter sealing.

Yes, closed-cell foam gaskets block water ingress. Open-cell foams are not suitable for waterproof sealing.

Thickness depends on gap size and compression range. The gasket should compress 20–40% to seal effectively.

Yes, foam gaskets absorb vibration and reduce noise. Material type and density influence damping performance.

All foams age gradually. Correct material selection and proper compression minimize compression set and performance loss.

Yes, foam gaskets can be die-cut or CNC-cut to precise shapes and tight tolerances for custom applications.

"We recently purchased rubber gaskets from Rubber Xperts INC. and were thoroughly impressed with their service. The team demonstrated a high level of professionalism and ensured we received top-quality products. Their assistance throughout the process was invaluable, and they delivered everything on time. We highly recommend Rubber Xperts INC. for their exceptional quality and outstanding customer support."

"Our dairy organization has been partnering with Rubber Xperts INC. for a while now, and we frequently procure silicone dairy hoses from them. Their customer service and engineering team are outstanding, always ensuring we receive the best products and support. This partnership has been a great success, and we highly recommend Rubber Xperts INC. for their professionalism, quality, and reliability."

With years of experience in hydraulic and pneumatic systems, Rubber Xperts INC makes top-quality rubber products like rubber o-rings, rubber seals, rubber pipes, rubber extrusions, rubber gaskets, rubber mounts, rubber hoses, and more.

We cater to various industries such as construction, aviation, agriculture, and marine. Quality is our priority, ensuring you get the best possible experience and product.

Our team can locate any product for you such as Seals, O-Rings, Gaskets, Pipes, Hoses, and more. If you need help finding a very specific product, reach out to us by phone, email, or contact form. If it exists, we'll find it for you.

We're available Monday-Friday

from 8:00 AM to 6:00 PM EST,

and Saturday from 8:00 AM to 12:00 PM EST.

Top-notch customer support from us,

whether it's before or after your purchase.

Buy easily through our website or

just give us a call.

Customize your ordering and packing preferences with our flexible solutions tailored to your needs.