What are rubber D-ring seals? Learn their functionalities, industry uses, installation methods, lifespan factors, benefits, and how they differ from O-ring seals.

Rubberxpert flange gaskets provide reliable sealing between mating flange surfaces. It prevents leaks in your piping systems carrying liquids or gases under pressure. They support high-pressure flange sealing while providing insulation, vibration damping, and chemical resistance in industrial environments.

Flange gaskets are designed for both durability and flexibility, allowing them to perform effectively across a wide range of temperatures. Rubber Xpert Inc manufactures and supplies custom flange gaskets engineered to meet ANSI, DIN, and JIS standards for demanding applications.

10% discount for bulk orders over $1,000

Buy flange gaskets in bulk directly from a manufacturer you can trust. Rubber Xpert Inc. is a bulk flange gasket supplier. Rubber Xpert Inc. supplies certified materials, consistent QC, OEM flange gasket manufacturing, custom flange gasket sizes, competitive pricing, and fast turnaround for industrial buyers.

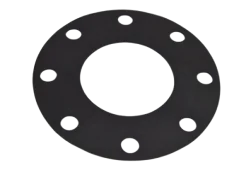

Full-Face Flange Gaskets (FF) are engineered for uniform load distribution and applications requiring reliable sealing, chemical stability, and consistent pressure performance across the entire flange surface. They deliver dependable sealing in systems where flange face protection, low bolt stress, and leak prevention are critical concerns.

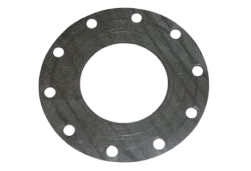

Ring-Type Flange Gaskets (RF) are engineered for higher-pressure flange connections and applications requiring concentrated sealing stress, enhanced pressure resistance, and reliable leak prevention within the bolt circle. They deliver consistent sealing performance in systems where elevated pressure, thermal cycling, and space-restricted flange faces are critical concerns.

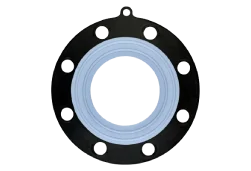

Spiral Wound Flange Gaskets are engineered for high-pressure and high-temperature applications requiring superior sealing integrity, mechanical strength, and resistance to thermal cycling. They deliver reliable sealing performance in environments where extreme pressure fluctuations, temperature variation, and aggressive media are critical concerns.

PTFE Flange Gaskets are engineered for chemically aggressive and high-purity applications requiring exceptional chemical resistance, non-reactivity, and stable sealing performance across wide temperature ranges. They deliver reliable sealing in environments where corrosive chemicals, contamination risk, and thermal variation are critical concerns.

Non-Metallic (Soft) Flange Gaskets are engineered for low-to-medium pressure applications requiring excellent compressibility, surface conformity, and dependable sealing performance. They deliver reliable sealing in environments where flange irregularities, vibration, and moderate temperature or chemical exposure are critical concerns.

Semi-Metallic Flange Gaskets are engineered for demanding industrial applications requiring a balance of strength, flexibility, and reliable sealing under elevated pressure and temperature conditions. They deliver consistent sealing performance in environments where thermal cycling, pressure fluctuation, and mechanical stress are critical concerns.

Rubber Xpert Inc. uses certified gasket materials and engineering-grade manufacturing processes to deliver precision-crafted flange gaskets designed for durability, sealing accuracy, and consistent industrial performance.

Every flange gasket is produced under strict quality controls to ensure reliable sealing across high-pressure, chemical, and temperature-sensitive operating environments.

We begin your flange gasket process by conducting a detailed review of your operating conditions, flange standards, pressure rating, temperature limits, chemical exposure, and dimensional tolerance. This review is to ensure that you have application-specific accuracy.

Our engineers convert requirements into precise CAD models, defining gasket geometry, bolt-circle alignment, thickness, and tolerance limits in accordance with ANSI, DIN, or JIS specifications.

Based on your performance demands, we select compliant materials such as EPDM, NBR, PTFE, CNAF, or composite grades to meet chemical compatibility, pressure, and temperature requirements.

Prototypes are produced for fit verification and functional testing. We ensure sealing performance, compression recovery, and dimensional accuracy before full-scale production.

Your approved designs move to CNC cutting, die-cutting, or molding processes to achieve consistent part geometry and repeatable tolerances at scale.

Each flange gasket batch undergoes dimensional inspection, material verification, and compliance checks to confirm adherence to specifications and performance standards.

Finished flange gaskets are securely packaged, labeled for traceability. Your orders are dispatched through reliable logistics channels for timely nationwide delivery.

Flange gaskets are sealing components installed between two mating flange surfaces to prevent leakage in piping and fluid transfer systems. Their primary function is to create a tight, uniform seal when compressed, ensuring safe and efficient containment of liquids or gases.

Flange gaskets are engineered to perform under varying temperatures, pressure levels, and chemical exposures while maintaining flexibility, compression recovery, and sealing integrity. Flange gaskets provide insulation, vibration damping, and resistance to aggressive media, depending on the material.

Industries rely on flange gaskets in oil and gas, chemical processing, water treatment, power generation, and HVAC systems to maintain system reliability, prevent downtime, and meet safety and compliance requirements in critical operations.

The types of flange gaskets available include the following:

Full-face flange gaskets are designed to cover the entire flange surface, including the bolt holes, providing uniform load distribution and broad sealing contact. They are made from soft materials such as rubber or compressed fiber, offering good flexibility, compressibility, and surface conformity.

Go for flange gaskets for low-pressure applications in water treatment, HVAC, and utility piping. However, they are not recommended for high-pressure or high-temperature environments due to limited stress concentration and material strength.

Ring-type flange gaskets are made to fit inside the bolt circle and focus sealing pressure on a smaller contact area. Its design allows for improved pressure handling compared to full-face designs.

Ring-type flange gaskets are manufactured from elastomers, PTFE, or composite materials. They provide reliable sealing, chemical resistance, and better blowout resistance. Ring-type gaskets are widely used in oil and gas, chemical processing, and industrial piping systems. However, correct alignment and flange face compatibility are critical for effective sealing.

RTJ (Ring-Type Joint) gaskets are precision-machined metallic gaskets designed to seat into specially grooved flanges, creating a metal-to-metal seal under extreme pressure. They are made from solid metals such as stainless steel or alloy steel, and offer exceptional pressure and temperature resistance with minimal leakage risk.

RTJ gaskets are best suited for high-pressure oil and gas, refinery, and petrochemical applications, but they require matching RTJ flanges and are not reusable once installed.

The materials used to manufacture flange gaskets include:

| Material | Operating Temperature | Compression Set | Chemical Resistance | Cost | Best For |

|---|---|---|---|---|---|

| EPDM | −40°C to +120°C | Low | Excellent (water, steam, mild chemicals) | Low | Water treatment, HVAC, outdoor piping |

| Neoprene | −30°C to +100°C | Moderate | Good (oils, weather, mild chemicals) | Low–Medium | Utility lines, refrigeration, and general industrial use |

| Nitrile (Buna-N) | −30°C to +120°C | Low–Moderate | Excellent (oils, fuels, hydrocarbons) | Medium | Oil & gas, hydraulic systems, fuel handling |

| Viton (FKM) | −20°C to +250°C | Very Low | Excellent (aggressive chemicals, solvents) | High | Chemical processing, petrochemical, high-temp sealing |

| Graphite | −200°C to +450°C | Very Low | Excellent (most chemicals, high pressure) | Medium–High | Steam systems, refineries, and power generation |

| PTFE (Teflon) | −200°C to +260°C | Moderate | Outstanding (near-universal resistance) | Medium | Corrosive fluids, pharma, food-grade applications |

To choose the right flange gasket, match the material size, temperature rating, pressure capacity, and operating environment to your specific application.

Select a gasket material chemically compatible with your system fluid or gas. Incompatibility leads to rapid degradation. Confirm your correct gasket size and flange standard, especially for die-cut gaskets.

You must also evaluate operating temperature and pressure limits to avoid gasket blowouts. Environmental factors like vibration, thermal cycling, and exposure conditions directly impact gasket durability and sealing stability.

Flange gaskets are commonly used in the following areas:

Flange gaskets are used to seal fluid transfer points in engines, exhaust systems, cooling lines, and fuel assemblies. They help prevent leaks, absorb vibration, and maintain pressure stability under continuous thermal cycling and mechanical stress.

In electronics manufacturing, flange gaskets provide sealing and insulation for enclosures, cooling systems, and protective housings. They help block moisture, dust, and chemical ingress while maintaining stable internal operating conditions.

Flange gaskets are found in pumps, compressors, pipelines, and process equipment where reliable sealing is critical. They ensure leak-free operation, reduce downtime, and protect machinery from pressure loss and contamination.

Flange gaskets seal processing lines, tanks, and transfer systems in food and beverage systems. They support hygienic operations by preventing contamination, handling temperature variation, and maintaining consistent sealing during washdowns.

Flange gaskets are used in medical gas lines, sterilization systems, and fluid-handling equipment. They provide precise, contamination-free sealing where safety, cleanliness, and material stability are essential.

Flange gaskets seal ducting, chillers, compressors, and coolant lines in HVAC and refrigeration systems. They help maintain system efficiency by preventing refrigerant leaks and handling pressure and temperature fluctuations.

Flange gaskets are critical in marine piping, fuel systems, and offshore platforms where corrosion resistance and pressure reliability are required. They ensure secure sealing in harsh environments exposed to saltwater, vibration, and extreme operating conditions.

The key features and benefits of flange gaskets include:

Flange gaskets are designed to perform reliably across temperature ranges from −200°C to +550°C, depending on material selection.

They maintain consistent sealing under low to high-pressure conditions, reducing the risk of system leaks and downtime.

Flange gasket is engineered to retain sealing integrity after repeated loading cycles, extending service life in dynamic systems.

They are manufactured to tight tolerance ranges (±0.1 mm) for proper flange alignment and uniform bolt load distribution.

Flange gaskets are available in elastomeric, non-metallic, and semi-metallic options to suit chemical, thermal, and mechanical demands.

They help dampen mechanical vibration, protecting connected equipment and improving system stability.

Flange gaskets are designed for long-term use with service life exceeding standard maintenance cycles when correctly specified and installed.

Follow these steps to install flange gaskets:

Clean both flange faces thoroughly to remove dirt, old gasket residue, rust, oil, and moisture. A clean, flat sealing surface prevents uneven compression and reduces leak risk.

Bring the flanges into proper alignment and verify that the bolt holes line up without forcing. Misalignment creates uneven gasket loading and causes premature failure.

Center the flange gasket correctly on the flange face (full-face or ring-type position), ensuring it sits flat with no folds or twists. Confirm the gasket ID/OD and bolt circle match the flange standard.

Insert bolts and tighten in a star (cross) pattern in gradual torque increments to achieve uniform compression. Avoid over-tightening, as excessive load can crush soft gaskets or distort the sealing surface.

Pressurize the system gradually and inspect the joint for leaks using the appropriate test method (pressure hold, bubble test, or approved plant procedure). Confirm performance under operating pressure and temperature where possible.

Recheck bolt torque after initial pressurization and thermal stabilization if your procedure requires it. Document the installation details (gasket type, material, thickness, and torque values) for maintenance traceability.

Here are some frequently asked questions about our Flange Gaskets to help you find the answers you need:

In normal operating conditions, flange gaskets last several years. Lifespan shortens when exposed to excessive temperature, pressure, or chemical mismatch, while proper material selection and installation extend service life.

Yes, but once compressed, most flange gaskets lose recovery. Reusing them increases leak risk, so replacing the gasket ensures proper sealing and system reliability.

Flange gasket leaks usually result from incorrect material selection, uneven bolt torque, flange misalignment, or surface damage. Addressing these factors restores sealing performance.

You know the gasket size to choose by matching the gasket to the flange standard, bolt circle, and nominal pipe size. Incorrect sizing leads to poor sealing, so ensure proper fit and compression.

Some gasket types are designed for high pressure, while others are not. Selecting the correct gasket construction and material prevents blowout and maintains sealing integrity.

"We recently purchased rubber gaskets from Rubber Xperts INC. and were thoroughly impressed with their service. The team demonstrated a high level of professionalism and ensured we received top-quality products. Their assistance throughout the process was invaluable, and they delivered everything on time. We highly recommend Rubber Xperts INC. for their exceptional quality and outstanding customer support."

"Our dairy organization has been partnering with Rubber Xperts INC. for a while now, and we frequently procure silicone dairy hoses from them. Their customer service and engineering team are outstanding, always ensuring we receive the best products and support. This partnership has been a great success, and we highly recommend Rubber Xperts INC. for their professionalism, quality, and reliability."

With years of experience in hydraulic and pneumatic systems, Rubber Xperts INC makes top-quality rubber products like rubber o-rings, rubber seals, rubber pipes, rubber extrusions, rubber gaskets, rubber mounts, rubber hoses, and more.

We cater to various industries such as construction, aviation, agriculture, and marine. Quality is our priority, ensuring you get the best possible experience and product.

Our team can locate any product for you such as Seals, O-Rings, Gaskets, Pipes, Hoses, and more. If you need help finding a very specific product, reach out to us by phone, email, or contact form. If it exists, we'll find it for you.

We're available Monday-Friday

from 8:00 AM to 6:00 PM EST,

and Saturday from 8:00 AM to 12:00 PM EST.

Top-notch customer support from us,

whether it's before or after your purchase.

Buy easily through our website or

just give us a call.

Customize your ordering and packing preferences with our flexible solutions tailored to your needs.