What are rubber D-ring seals? Learn their functionalities, industry uses, installation methods, lifespan factors, benefits, and how they differ from O-ring seals.

Die cut gaskets provide precision-shaped sealing solutions used for sealing, cushioning, spacing, insulation, and vibration damping across industrial assemblies. They deliver reliable performance through controlled thickness, flexibility, and material compatibility across wide temperature and pressure ranges.

The die-cutting process ensures tight tolerances, repeatable accuracy, and clean edges for a consistent fit. Rubber Xpert Inc. manufactures custom die cut gaskets using advanced rotary, flatbed, CNC, and kiss-cutting technologies.

10% discount for bulk orders over $1,000

Buy die cut gaskets in bulk directly from a manufacturer equipped to deliver certified materials, consistent quality control, and precision-cut custom dimensions. Rubber Xpert Inc. supports OEM production with competitive pricing, scalable volumes, and fast turnaround for your industrial and commercial applications.

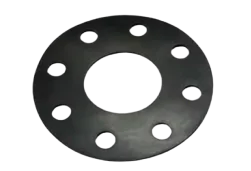

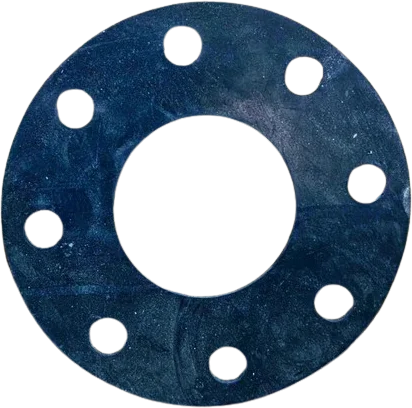

Die Cut Rubber Gaskets are engineered for flexible sealing applications requiring elasticity, vibration absorption, and reliable compression recovery. They deliver consistent sealing performance in environments where movement, mild pressure, and surface irregularities are a concern.

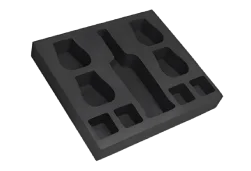

Die Cut Foam Gaskets are engineered for lightweight sealing and cushioning applications requiring compressibility, thermal insulation, and gap filling. They deliver effective sealing where low bolt load and surface inconsistency are critical concerns.

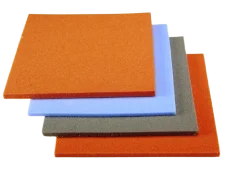

Die Cut Sponge Gaskets are engineered for sealing applications requiring superior compression recovery, moisture resistance, and vibration isolation. They deliver dependable sealing in environments where repeated compression and environmental exposure are concerns.

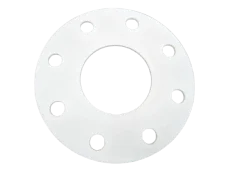

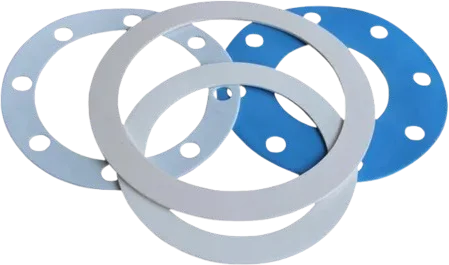

Die Cut PTFE Gaskets are engineered for chemically aggressive applications requiring inertness, thermal stability, and low-friction sealing. They deliver reliable performance where corrosive media and purity requirements are critical challenges.

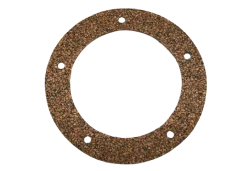

Die Cut Cork & Rubber-Cork Gaskets are engineered for low-pressure sealing and vibration control applications requiring compressibility and oil resistance. They deliver effective sealing where irregular flange surfaces and fluid exposure are concerns.

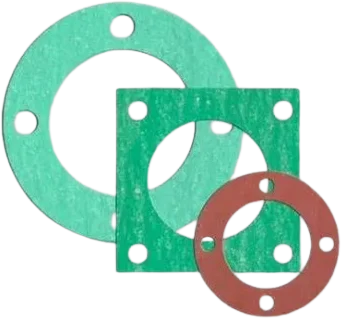

Die Cut Fiber Gaskets are engineered for pressure-resistant sealing applications requiring dimensional stability, heat resistance, and mechanical strength. They deliver consistent sealing in environments where pressure, heat, and chemical exposure must be controlled.

Rubber Xpert Inc. uses certified gasket materials and engineering-grade manufacturing processes to deliver precision-crafted die cut gaskets designed for dimensional accuracy, durability, and consistent sealing performance. Every die cut gasket is produced under strict quality controls to ensure reliability across demanding operating environments and tight tolerance requirements.

Your custom die cut gasket process begins with a detailed assessment of application requirements, including sealing function, operating temperature, pressure, chemical exposure, dimensional constraints, and tolerance limits.

Our engineering teams develop precise CAD models that define gasket geometry, cut profiles, thickness, and dimensional tolerances. We ensure compliance with both functional and industry-specific standards.

We use appropriate materials selected based on performance criteria such as flexibility, compression set, thermal stability, and chemical compatibility with the operating environment.

Prototype gaskets are produced for fit, compression, and functional validation, ensuring dimensional accuracy and performance compliance before full-scale production.

The approved designs move into rotary die-cutting, flatbed die-cutting, CNC cutting, or kiss-cutting processes to achieve repeatable accuracy and production consistency.

Each production batch undergoes dimensional inspection, material verification, and compliance checks against specified tolerances and performance requirements.

Finished die cut gaskets are packaged for protection, labeled for traceability. We ship through reliable logistics channels to ensure on-time nationwide delivery.

Die cut gaskets are precision-manufactured sealing components produced by cutting gasket materials into exact shapes and dimensions to match specific assemblies. Their core function is to create reliable seals, spacing, cushioning, insulation, or vibration control between mating surfaces.

Die cut gaskets are engineered to perform across a wide range of temperatures, pressures, and environmental conditions while maintaining flexibility, compression recovery, and dimensional accuracy. Die cut gaskets also provide chemical resistance, thermal insulation, and noise or vibration damping, depending on their material.

Industries like automotive, electronics, industrial machinery, HVAC, and medical equipment use die cut gaskets because they offer repeatable precision, consistent sealing performance, and efficient integration into high-volume production environments.

The types of die cut gaskets available include:

Die cut rubber gaskets are precision-cut elastomeric seals designed to provide flexible, compressible sealing between mating surfaces. They offer good elasticity, vibration damping, and resistance to wear, making them suitable for automotive, HVAC, and general industrial equipment. However, you must consider oil, fuel, or chemical exposure when selecting die cut rubber gaskets to avoid premature degradation.

Die cut foam gaskets are lightweight sealing and cushioning components made from closed-cell or open-cell foams. They provide excellent compressibility, thermal insulation, and gap-filling capability, making them ideal for electronics enclosures, appliances, and low-load sealing applications. Die cut foam gasket limitation lies in lower pressure resistance compared to solid rubber or fiber materials.

Die cut sponge gaskets are soft, cellular rubber gaskets engineered for high compression recovery and environmental sealing. They perform well in applications requiring moisture resistance, vibration isolation, and repeated compression, such as outdoor enclosures and HVAC systems. However, they are best suited for low-to-medium pressure environments due to their soft structure.

Die cut PTFE (Teflon) gaskets are chemically inert sealing components used where aggressive chemicals, high purity, and temperature stability are required. They offer excellent chemical resistance, low friction, and wide temperature tolerance.

Die cut PTFE gaskets are ideal for chemical processing, pharmaceutical, and food-grade systems. However, PTFE’s low compressibility means proper bolt load is critical for effective sealing.

Die cut PTFE (Teflon) gaskets are chemically inert sealing components used where aggressive chemicals, high purity, and temperature stability are required. They offer excellent chemical resistance, low friction, and wide temperature tolerance.

Die cut PTFE gaskets are ideal for chemical processing, pharmaceutical, and food-grade systems. However, PTFE’s low compressibility means proper bolt load is critical for effective sealing.

Die cut fiber gaskets (including non-asbestos and cellulose fiber) are rigid or semi-rigid sealing materials engineered for pressure resistance and dimensional stability. They perform well in pumps, valves, and industrial piping systems exposed to heat and pressure.

Proper material selection is important to ensure their chemical compatibility and prevent brittleness under extreme conditions.

Die cut gaskets are manufactured from carefully selected materials, each chosen based on operating temperature, flexibility, and resistance to chemicals or environmental exposure.

The materials used to manufacture die cut gaskets include:

| Material | Operating Temperature | Compression Set | Chemical Resistance | Cost | Best For |

|---|---|---|---|---|---|

| Rubber (EPDM, NBR, Neoprene) | −40°C to +120°C | Low | Good to Excellent (material-dependent) | Low–Medium | Flexible Sealing, Vibration Damping, General Industrial Use |

| Foam & Sponge | −30°C to +100°C | Moderate | Limited to Moderate | Low | Cushioning, Insulation, Low-load Sealing |

| PTFE (Teflon) | −200°C to +260°C | Moderate | Outstanding | Medium | Chemically Aggressive, High-Purity Applications |

| Fiber & Composite (Non-Asbestos, Cork-Rubber) | −40°C to +250°C | Low–Moderate | Good | Medium | Pressure-resistant Sealing in Pumps, Valves, Machinery |

You choose the right die cut gasket by aligning material compatibility, precise sizing, operating temperature, pressure load, and environmental exposure with your application requirements. A correct match ensures consistent sealing, proper compression, and long service life.

When you choose a die cut gasket, consider chemical resistance, tolerance accuracy, and whether the gasket will face vibration, moisture, or thermal cycling. Following these gasket buying tips helps prevent premature failure and supports reliable performance across production and operating conditions.

Die cut gaskets are widely used across industries where precise sealing, cushioning, insulation, and vibration control are required. Their ability to be manufactured to exact shapes and tolerances makes them ideal for both high-volume production and application-specific assemblies.

Industries where die cut gaskets are commonly used include:

Die cut gaskets are used in engines, fuel systems, and body assemblies to provide precise sealing, vibration reduction, and durability under heat, pressure, and constant motion.

Die cut gaskets seal electronic enclosures and control units. They protect sensitive components from dust, moisture, and heat while supporting compact, precision-fit designs.

Die cut gaskets are installed in pumps, compressors, and equipment housings to prevent leaks, absorb vibration, and support reliable, continuous operation.

They are used in processing equipment and transfer systems to maintain hygienic sealing, withstand frequent washdowns, and support consistent production performance.

Die cut gaskets provide accurate, contamination-resistant sealing in medical devices and fluid systems where precision and material stability are critical.

Die cut gaskets seal ducts, compressors, and cooling units, helping improve energy efficiency and prevent air or refrigerant leakage.

Die cut gaskets protect outdoor and marine enclosures by delivering weather-resistant sealing against moisture, UV exposure, and temperature variation.

The key features and benefits of die cut gaskets include the following:

Die cut gaskets are manufactured to tight tolerances of ±0.1 mm for consistent fit and repeatable sealing performance.

They are designed to operate reliably across −200°C to +260°C, depending on material selection.

Optimized die-cut profiles reduce material waste while maintaining functional sealing coverage.

Die cut gaskets maintain sealing integrity over repeated compression cycles, supporting long service life.

They are suitable for both prototyping and high-volume OEM production without dimensional variation.

They are engineered to last through standard maintenance intervals when correctly specified and installed.

Follow these steps to install die cut gaskets:

Clean all mating surfaces to remove dust, oil, moisture, and residue. Proper surface preparation ensures uniform contact and prevents sealing gaps.

Align the components correctly before installation, ensuring bolt holes and contact surfaces match without forcing. Misalignment causes uneven compression and premature gasket failure.

Position the die cut gasket accurately within the sealing area, confirming correct orientation, profile fit, and full surface contact.

Apply fastening force evenly using a controlled tightening sequence to achieve uniform compression. Avoid over-tightening, as excessive load can deform the gasket.

Gradually bring the system to operating conditions and inspect for leaks or loss of sealing performance using approved testing methods.

Reinspect the assembly after initial operation, verifying compression stability and fastener integrity to ensure long-term sealing reliability.

Here are some frequently asked questions about our Die Cut Gaskets to help you find the answers you need:

Die cut gaskets generally last through standard maintenance cycles. Service life depends on material selection, operating temperature, pressure, and environmental exposure.

Most die cut gaskets are not reusable. Compression and deformation reduce sealing effectiveness once the gasket is removed.

Die cut gaskets can be produced to tight dimensional tolerances. Typical tolerance ranges reach ±0.1 mm, depending on material and cutting method.

Some materials perform well at elevated temperatures. PTFE and fiber-based die cut gaskets are suitable for higher temperature ranges compared to foam or sponge materials.

Die cut gasket failure is commonly caused by incorrect material selection, improper compression, misalignment, or exposure beyond rated temperature or chemical limits.

"We recently purchased rubber gaskets from Rubber Xperts INC. and were thoroughly impressed with their service. The team demonstrated a high level of professionalism and ensured we received top-quality products. Their assistance throughout the process was invaluable, and they delivered everything on time. We highly recommend Rubber Xperts INC. for their exceptional quality and outstanding customer support."

"Our dairy organization has been partnering with Rubber Xperts INC. for a while now, and we frequently procure silicone dairy hoses from them. Their customer service and engineering team are outstanding, always ensuring we receive the best products and support. This partnership has been a great success, and we highly recommend Rubber Xperts INC. for their professionalism, quality, and reliability."

With years of experience in hydraulic and pneumatic systems, Rubber Xperts INC makes top-quality rubber products like rubber o-rings, rubber seals, rubber pipes, rubber extrusions, rubber gaskets, rubber mounts, rubber hoses, and more.

We cater to various industries such as construction, aviation, agriculture, and marine. Quality is our priority, ensuring you get the best possible experience and product.

Our team can locate any product for you such as Seals, O-Rings, Gaskets, Pipes, Hoses, and more. If you need help finding a very specific product, reach out to us by phone, email, or contact form. If it exists, we'll find it for you.

We're available Monday-Friday

from 8:00 AM to 6:00 PM EST,

and Saturday from 8:00 AM to 12:00 PM EST.

Top-notch customer support from us,

whether it's before or after your purchase.

Buy easily through our website or

just give us a call.

Customize your ordering and packing preferences with our flexible solutions tailored to your needs.