Difference Between Nitrile and Viton O-Rings: Which One You Need?

Discover the key differences between Nitrile and Viton O-rings in our comprehensive blog, including their factors and ideal applications for various industries.

Rubber O-Rings provide a simple yet highly effective sealing solution for preventing leaks, maintaining pressure, and ensuring smooth performance for many use cases. Our O-rings deliver durability, chemical resistance, and a perfect fit for every need. They’re the solution you need, whether you work on industrial machinery, automotive engines, or residential plumbing systems.

Find the exact O-rings you need, available in multiple materials, sizes, and industry-grade standards. Bulk ordering options are available for businesses that require reliable stock for maintenance and production purposes.

FDA-approved seals for extreme temps (-60°C to 230°C) and sterile environments

All-weather sealing solution resists UV, ozone, water, and steam up to 150°C.

Versatile general-purpose seals handle refrigerants, oils, and moderate chemicals.

Aerospace-grade sealing for jet fuels, hydraulics, and extreme cold environments

Premium chemical resistance up to 200°C for aggressive industrial environments

Heavy-duty sealing for high-pressure hydraulics and abrasive oil environments

Industry-standard oil and fuel sealing with proven reliability and value

Maximum wear resistance for moving parts and high-friction applications

Flexible TPV sealing for potable water and chemical processing systems

Ultra-low permeability sealing for vacuum systems and gas containment

High-strength elasticity for water systems and non-petroleum applications

Automotive-grade sealing for engine oils and transmission fluids at high temps

Technical review of your O-ring requirements

Detailed specifications and pricing

Precision molding and quality testing

Final inspection and fast delivery

Rubber O-rings are circular elastomer seals designed to fit into grooves and prevent the passage of liquids or gases. Also known as O-ring seals or O-ring gaskets, these flexible sealing elements create airtight and watertight barriers by compressing between two surfaces under pressure or movement.

Their primary function is maintaining leak-proof connections in industries ranging from plumbing and automotive to manufacturing and chemical processing. According to a Research Nester Report, the O-ring market in the aerospace equipment segment is expected to gain a 52% share by 2037, highlighting the critical role O-rings play in fueling industrial growth.

The elastomeric properties of O-rings allow them to deform and fill gaps while returning to their original shape, ensuring consistent sealing performance under varying conditions. This adaptability, combined with their cost-effectiveness and ease of installation, makes them indispensable components across countless applications.

The different types and classifications of rubber o-rings are highlighted below:

Static O-rings are designed for stationary applications where there's no movement between sealed surfaces. These seals excel in pipelines, flanges, and valve covers, providing reliable containment without wear from motion. Static O-rings demonstrate exceptional longevity, with studies showing they last up to three times longer than dynamic seals under identical conditions due to reduced mechanical stress.

Dynamic O-rings handle applications involving movement, such as hydraulic pistons, rotating shafts, and reciprocating machinery. These seals must withstand continuous friction while maintaining pressure integrity, requiring specialized materials like polyurethane or Viton for enhanced wear resistance.

Standard Torus O-Rings feature the traditional circular cross-section and represent the most versatile sealing solution for both static and dynamic applications.

Square O-rings have a square cross-section designed to provide tighter seals and reduce rolling or extrusion under high pressure, making them ideal for precision hydraulic systems.

Specialized Shapes include X-rings and quad rings that offer multiple sealing lips for enhanced leak protection in critical applications.

Food-Grade O-Rings are manufactured using FDA-approved materials like silicone or EPDM, ensuring compliance with food safety standards for processing and packaging equipment.

Medical O-Rings use biocompatible materials for sterile applications in syringes, pumps, and diagnostic equipment, maintaining patient safety and equipment reliability.

Automotive O-Rings withstand high temperatures, pressures, and exposure to oils and fuels in engines, transmissions, and braking systems.

Aerospace O-Rings are engineered for extreme conditions in aircraft and spacecraft systems, providing reliable sealing for fuel systems, hydraulics, and cabin pressurization.

The common materials used in rubber o-ring manufacturing depend on the different applications to ensure optimal performance and longevity. The common materials are listed in the table below:

| Material | Temp Range | Chemical Resistance | Durability | Cost Level | Best Applications |

|---|---|---|---|---|---|

| NBR (Buna-N) | -40°C to 120°C | Oils and Fuels | High | Low | Automotive, hydraulic systems |

| EPDM | -50°C to 150°C | Water, Steam, Weather | High | Medium | Plumbing, HVAC, outdoor use |

| Viton/FKM | -20°C to 200°C | Solvents and Chemicals | Very High | High | Chemical processing, aerospace |

| Silicone | -60°C to 230°C | Mild Chemicals and Heat | Medium | Medium | Medical, food-grade, extreme temps |

| Neoprene | -40°C to 120°C | Weather and Abrasion | Medium | Medium | General-purpose, refrigeration |

| Polyurethane | -30°C to 80°C | Abrasion and Wear | Very High | Medium | Dynamic sealing, high-pressure |

| Fluorosilicone | -65°C to 175°C | Fuels and Low Temps | High | High | Aerospace, fuel systems |

To choose the best rubber o-ring material, consider the following factors:

Operating temperature range significantly impacts material choice. Silicone excels in extreme temperatures, while NBR suits moderate temperature applications cost-effectively.

Exposure to oils, fuels, solvents, or cleaning agents requires specific material properties. Viton handles aggressive chemicals, while EPDM resists water and steam.

High-pressure applications demand robust materials like polyurethane or require backup rings to prevent extrusion and failure.

Moving applications need materials with enhanced wear resistance, while static seals can use more cost-effective options.

Food, medical, and pharmaceutical applications require FDA-approved materials like silicone or specific EPDM grades.

Rubber o-rings are commonly used in the following sectors:

O-rings are essential in engines, fuel injectors, brake systems, and transmission components. NBR and Viton materials handle exposure to oils, fuels, and high temperatures while maintaining reliable sealing performance. Critical applications include fuel system sealing, engine oil containment, and hydraulic brake fluid systems.

Pumps, compressors, and hydraulic systems rely on O-rings for leak-free operation. These applications often involve high pressures and continuous operation, requiring durable materials like polyurethane for dynamic seals or EPDM for water-based systems.

Water systems, pipe connections, and filtration equipment use O-rings to prevent leaks and maintain system pressure. EPDM excels in these applications due to its water resistance and UV stability for outdoor installations.

Processing machinery requires FDA-approved silicone or EPDM O-rings that withstand sterilization cycles and cleaning agents while maintaining food safety compliance. These seals prevent contamination and ensure product purity.

Harsh environment sealing involves exposure to aggressive chemicals, saltwater, and extreme weather conditions. Viton and specialized fluoroelastomers provide the necessary chemical resistance for reliable long-term performance.

Critical sealing applications in fuel systems, hydraulics, and cabin pressurization demand materials like fluorosilicone that maintain integrity under extreme temperature variations and high pressures.

Environmental protection sealing prevents dust, moisture, and contaminant ingress in sensitive equipment. Silicone O-rings provide stable sealing while accommodating thermal expansion cycles.

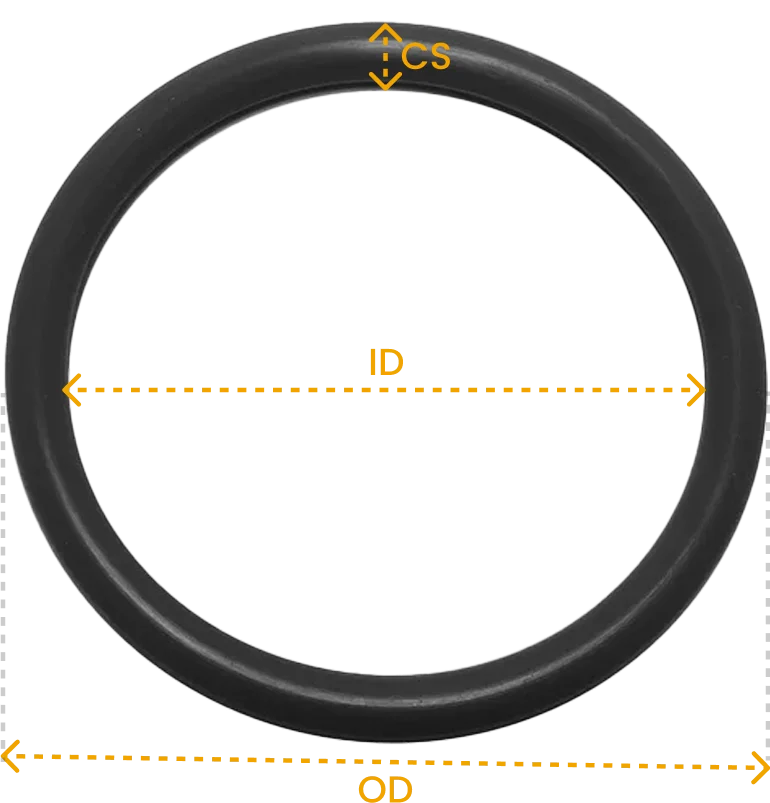

To determine the rubber o-ring sizes, consider the following O-ring dimensions:

The key features and benefits of the rubber o-rings Rubber Xperts Inc sells are highlighted below:

Provides superior airtight and watertight sealing to prevent fluid or gas leakage in critical systems such as engines, pipelines, and HVAC units.

Simple design allows for quick maintenance, minimizing labor costs and operational interruptions.

Offers precise compatibility with global equipment and machinery, reducing the risk of seal failure.

Withstand exposure to oils, fuels, steam, and solvents while performing in both high-temperature and cryogenic conditions.

Suitable for automotive, industrial, marine, chemical, and food-grade systems, supporting diverse operational needs.

To install Rubber O-rings, consider the following steps:

Clean the groove and surrounding area thoroughly, removing debris, old lubricant, or metal shavings. Inspect the O-ring for cuts, cracks, or deformation that could compromise sealing integrity.

Apply a compatible lubricant to reduce friction during installation. Use silicone-based grease for general applications or synthetic O-ring oil for specialized requirements. Ensure lubricant compatibility with the O-ring material and system fluids.

Position the O-ring without excessive stretching or twisting. Use plastic installation picks from O-ring mounting kits to avoid damage. Roll the O-ring into place rather than pulling aggressively to prevent overstretching.

Ensure even seating in the groove with no pinching or bulging. Check alignment to maintain consistent compression across the entire circumference.

Test the assembly under operational conditions to verify sealing integrity. Perform pressure testing according to manufacturer specifications to confirm reliable performance.

Follow these compression ratios to ensure effective sealing and longer O-rings life.

15-25% compression ratio ensures effective sealing without excessive stress

10-20% compression balances sealing efficiency with reduced wear

Over-compression causes material fatigue and extrusion

Under-compression results in poor sealing and system leaks

To maintain rubber o-rings, consider the following best practices:

Implement routine visual inspections to identify wear, cracking, or deformation before failure occurs. Early detection prevents costly system downtime and equipment damage.

Use lint-free cloths and compatible solvents to maintain clean sealing surfaces. Proper cleaning prevents contamination that could compromise seal effectiveness.

Reapply compatible lubricants during service intervals to reduce friction and extend O-ring life in dynamic applications.

Replace O-rings showing signs of hardening, cracking, permanent deformation, or chemical degradation to maintain system reliability.

The common issues linked to rubber o-rings are listed below:

To test rubber o-rings' performance and quality, consider the following options:

Pressure Testing: verifies sealing integrity under operational conditions according to standards like ASTM F2378.

Chemical Compatibility Testing follows ISO 1817 and ASTM D471 methods to ensure material resistance to operational fluids.

Temperature Cycling: validates performance across expected operating temperature ranges

Compression Set Testing measures material recovery after prolonged compression to predict service life.

The main difference between an O-ring and a seal is that an O-ring is a specific type of circular sealing element, while a seal is a broader category encompassing various shapes and designs for containing fluids or gases.

You should use Rubber O-rings when the application requires a simple, versatile, and leak-proof solution for sealing under dynamic or static conditions. Conversely, Gaskets are better suited for flat surfaces or irregular shapes requiring a broader sealing area. Rubber O-rings are ideal for pressure systems and fluid containment, while gaskets excel in applications like machinery gaskets or flanged connections.

Yes, rubber O-ring seals can be made from eco-friendly materials by using sustainable rubber compound types derived from natural or recycled sources. Natural rubber or biodegradable alternatives are formulated to meet specific sealing needs, although they might have chemical or heat resistance limitations compared to synthetic rubbers like Viton (FKM). These eco-friendly solutions are increasingly popular in industries prioritising sustainability without compromising seal performance tracking.

Viton/FKM and EPDM O-rings perform best in chemical-heavy environments. Viton excels against solvents and fuels, while EPDM is suitable for water, steam, and some mild chemicals.

Viton/FKM is the most reliable for solvents and fuels, while NBR is suitable for oils and standard fuels but not for harsh chemicals.

Yes. Silicone O-rings can tolerate extreme cold (-60°C), and Viton/FKM can handle up to 200°C or more.

EPDM and Neoprene O-rings are excellent for UV, weather, and marine exposure.

Inspect quarterly for critical systems and replace annually or sooner if exposed to high pressure, heat, or chemicals.

Yes. Rubber Xperts Inc offers custom O-rings and seals for regulated industries and can meet ISO, ASTM, and FDA requirements.

Common causes include over-compression, chemical attack, heat degradation, and improper storage. Use compatible materials and follow installation best practices.

Yes. Store in a cool, dry, and dark place, away from UV exposure, ozone, or chemical vapors.

Yes. We provide bulk supply and OEM support with competitive pricing for industrial buyers.

It’s not recommended. O-rings may deform or pick up debris; replacing them ensures a reliable seal.

Measure the inner diameter (ID), outer diameter (OD), and cross-section using a caliper or O-ring sizing chart.

Yes. Silicone and Viton/FKM O-rings handle the highest temperature ranges.

Replacement depends on material and application. In standard conditions, annual inspection and replacement are recommended.

Yes. Contact us for custom O-ring kits, bulk options, and special size orders.

"We recently purchased rubber gaskets from Rubber Xperts INC. and were thoroughly impressed with their service. The team demonstrated a high level of professionalism and ensured we received top-quality products. Their assistance throughout the process was invaluable, and they delivered everything on time. We highly recommend Rubber Xperts INC. for their exceptional quality and outstanding customer support."

"Our dairy organization has been partnering with Rubber Xperts INC. for a while now, and we frequently procure silicone dairy hoses from them. Their customer service and engineering team are outstanding, always ensuring we receive the best products and support. This partnership has been a great success, and we highly recommend Rubber Xperts INC. for their professionalism, quality, and reliability."

With years of experience in hydraulic and pneumatic systems, Rubber Xperts INC makes top-quality rubber products like rubber o-rings, rubber seals, rubber pipes, rubber extrusions, rubber gaskets, rubber mounts, rubber hoses, and more.

We cater to various industries such as construction, aviation, agriculture, and marine. Quality is our priority, ensuring you get the best possible experience and product.

Our team can locate any product for you such as Seals, O-Rings, Gaskets, Pipes, Hoses, and more. If you need help finding a very specific product, reach out to us by phone, email, or contact form. If it exists, we'll find it for you.

We're available Monday-Friday

from 8:00 AM to 6:00 PM EST,

and Saturday from 8:00 AM to 12:00 PM EST.

Top-notch customer support from us,

whether it's before or after your purchase.

Buy easily through our website or

just give us a call.

Customize your ordering and packing preferences with our flexible solutions tailored to your needs.