Industrial Gaskets: Types, Applications, Materials, Installation, Compliance Standards

What is an industrial gasket? Explore types, applications, materials, installation process, compliance standards, and the three main gasket categories.

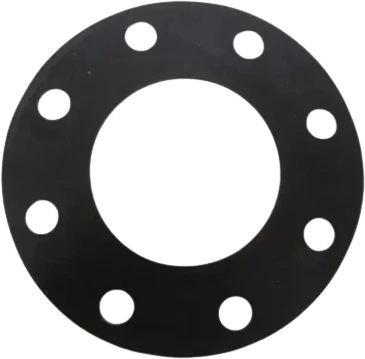

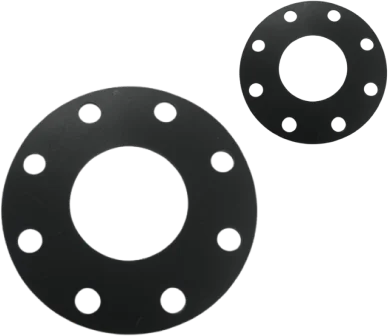

Rubber gaskets deliver critical sealing performance between flat mating surfaces, preventing leaks and maintaining pressure integrity across demanding industrial environments. Engineered from advanced elastomer compounds, these compressible seals conform to surface irregularities while withstanding extreme temperatures, aggressive chemicals, and high-pressure conditions.

Whether you need flange gaskets for piping systems, valve gaskets for process equipment, or custom die-cut profiles for specialized machinery, our comprehensive gasket portfolio ensures reliable, long-lasting sealing performance.

10% discount for bulk orders over $1,000

Browse our comprehensive selection of rubber gaskets below. Choose by material type, thickness, chemical compatibility, and temperature rating.

Precision-manufactured sealing components created using advanced die-cutting or water-jet technology for exact specifications and complex geometries.

High-purity elastomeric seals engineered for extreme temperature applications and FDA-regulated environments. Maintains flexibility from cryogenic to high-heat while remaining completely non-toxic.

Versatile general-purpose seals with balanced chemical resistance, weather durability, and flame-resistant properties. Ideal for applications with varying environmental conditions.

Weather and UV-resistant seals engineered for outdoor plumbing, hot water systems, and steam applications.

Ultra-chemical-resistant seals with near-universal chemical compatibility for aggressive acids, strong bases, and high-purity applications. Chemically inert to virtually all industrial chemicals.

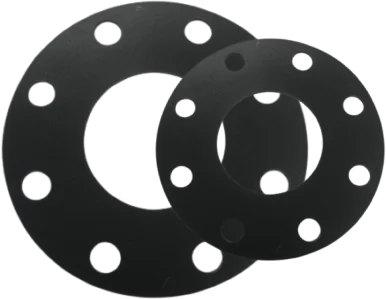

Pre-cut sealing components dimensioned for ANSI, DIN, and JIS pipe flange connections. Ready-to-install design eliminates field cutting and ensures proper fit.

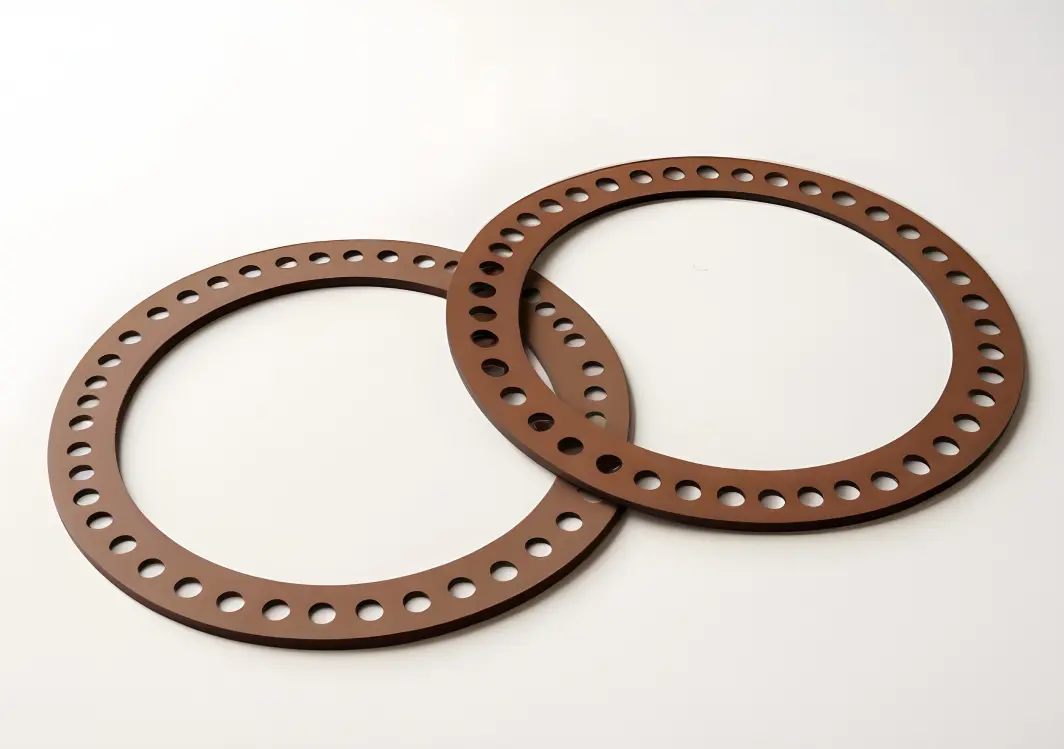

Large-diameter custom seals manufactured by heat-vulcanizing precision-cut sections together. Eliminates size limitations for oversized or specialty applications.

Oil and fuel-resistant seals specifically engineered for automotive engines, hydraulic systems, and petroleum-based fluid applications. Balances oil resistance with cost-effectiveness.

At Rubber Xperts Inc, we combine three decades of gasket engineering expertise with modern manufacturing capabilities.

Our engineers evaluate your sealing requirements, including fluid type, temperature extremes, pressure levels, and environmental conditions. We recommend optimal material formulations and thickness specifications based on bolt-load calculations and surface finish analysis.

For custom applications, we develop detailed gasket designs from your CAD files, physical samples, or dimensional specifications. Comprehensive quotes include material specifications, quantity pricing, tooling costs, and lead times.

Critical applications receive prototype gaskets for fit verification and performance validation in your actual operating conditions. We incorporate feedback and optimize designs before committing to full production.

Volume production utilizes precision die-cutting, compression molding, or water-jet cutting, depending on complexity and quantity. Every batch undergoes dimensional inspection, hardness testing, and visual quality control per ISO 9001 protocols.

Pre-shipment inspection verifies correct materials, dimensions, quantities, and packaging. Products ship in moisture-barrier packaging to preserve material properties during transit. Tracking information is provided at the time of shipment with delivery confirmation.

Rubber gaskets are flat elastomeric sealing components designed to fill the space between two mating surfaces, preventing leakage of fluids or gases while under compression. Unlike O-rings or dynamic seals that accommodate movement, gaskets create static seals in bolted flanges, threaded connections, and machinery housings where surfaces remain stationary during operation.

Their essential value lies in three critical functions: leak prevention through conformability to surface imperfections (compensating for machining marks, scratches, and flatness variations), load distribution across bolted joints (preventing stress concentration and surface damage), and vibration damping (reducing noise transmission and protecting against mechanical fatigue).

Industries depend on rubber gaskets because rigid metal-to-metal contact cannot reliably seal due to microscopic surface irregularities—even precision-machined surfaces have peaks and valleys measured in micrometers.

Rubber's compressible nature allows it to deform and fill these voids under bolt load, creating a continuous seal barrier. This compression also provides resilience, allowing gaskets to maintain sealing force even when thermal cycling causes dimensional changes or when bolt loads relax over time due to embedment or creep.

The gasket's ability to absorb tolerances makes it indispensable in manufacturing—it eliminates the need for perfect surface finishes and precise flatness control, significantly reducing machining costs while ensuring reliable sealing performance.

In high-consequence applications like pressure vessels, chemical processing equipment, and automotive engines, gasket failure can result in hazardous leaks, equipment damage, environmental contamination, or safety incidents, making proper gasket selection and installation critical engineering decisions.

The different types of rubber gaskets are highlighted below:

EPDM (Ethylene Propylene Diene Monomer) gaskets excel in water-based systems, steam applications, and outdoor environments where UV and ozone exposure would rapidly degrade other materials.

Their saturated polymer backbone lacks the double bonds vulnerable to oxidative attack, providing exceptional weathering resistance. These gaskets maintain flexibility and sealing force through temperature cycling from -40°C to +120°C, making them the standard choice for HVAC systems, hot water piping, and outdoor plumbing installations.

The specialty of EPDM lies in its superior steam resistance—it doesn't harden or crack even after prolonged exposure to superheated steam. While incompatible with petroleum oils and fuels due to its polar nature, EPDM offers excellent resistance to alkaline chemicals, ketones, and automotive brake fluids.

Nitrile gaskets are specifically engineered for petroleum-based fluid resistance, making them the industry standard for automotive oil pans, fuel systems, and hydraulic equipment. The acrylonitrile content (18-40%) determines oil resistance—higher nitrile grades resist aggressive fuels and lubricants but sacrifice low-temperature flexibility.

These gaskets maintain dimensional stability and sealing force when exposed to mineral oils, hydraulic fluids, and aliphatic hydrocarbons that would cause other rubbers to swell dramatically. Their specialty is balancing oil resistance with mechanical properties and cost-effectiveness, though they're unsuitable for aromatic fuels with high benzene content or exposure to strong oxidizers.

The benefit is reliable sealing in oily environments at a fraction of the cost of fluoroelastomers, making them economical for high-volume automotive and industrial applications where oil contact is inevitable.

Silicone gaskets provide the broadest usable temperature range (-60°C to +230°C) of any elastomer, maintaining flexibility at extreme cold while resisting degradation at temperatures that would destroy organic rubbers.

Their inorganic silicon-oxygen polymer backbone provides inherent thermal stability and physiological inertness, making them the only choice for many FDA-regulated applications. Available in platinum-cured (highest purity, medical/food grade) or peroxide-cured (industrial grade) formulations, silicone gaskets resist aging, ozone, and many chemicals while remaining completely tasteless and odorless.

Neoprene gaskets offer balanced performance across multiple properties—moderate oil resistance, good weather resistance, and a reasonable temperature range—making them versatile for general-purpose applications where specialized performance isn't required.

The chlorine atoms in the polymer backbone provide flame resistance and moderate chemical resistance not found in natural rubber. These gaskets perform reliably in refrigeration systems (resist refrigerants), HVAC equipment (outdoor durability), and marine environments (saltwater exposure).

Viton gaskets represent the premium tier for chemical resistance, with fluorine atoms bonded to the polymer backbone providing exceptional resistance to acids, petroleum products, and high-temperature fluids that aggressively attack other elastomers.

These gaskets maintain sealing integrity in continuous service up to 200°C (intermittent to 230°C) while resisting concentrated sulfuric acid, aromatic hydrocarbons, chlorinated solvents, and other aggressive chemicals.

Natural rubber gaskets offer superior physical properties—highest tensile strength, tear resistance, and elasticity among all rubbers—at the lowest material cost. Harvested from Hevea brasiliensis trees, NR provides excellent water resistance and flexibility for indoor applications not involving oils or significant ozone exposure.

These gaskets excel in dynamic sealing applications requiring resilience and energy absorption, such as pump housings and vibration-dampening applications.

SBR gaskets are synthetic alternatives to natural rubber, offering similar properties with better aging resistance and more consistent quality. These versatile gaskets handle water, mild chemicals, and ambient temperature conditions reliably in construction equipment, water treatment facilities, and general machinery. The styrene content provides abrasion resistance, while butadiene contributes flexibility, creating a balanced general-purpose material.

Food-grade gaskets are formulated with FDA-compliant compounds manufactured under stringent controls to prevent contamination. These gaskets feature smooth, non-porous surfaces that resist bacterial growth and facilitate CIP (clean-in-place) sanitization procedures. They are manufactured from platinum-cured silicone or FDA-compliant EPDM, are tasteless, odorless, and won't leach compounds into processed foods or beverages.

PTFE gaskets provide near-universal chemical resistance, remaining inert to virtually all chemicals except molten alkali metals and elemental fluorine. These gaskets withstand temperature extremes from cryogenic to +260°C while exhibiting the lowest coefficient of friction of any solid material. Available as virgin PTFE (100% polymer), filled grades (with glass, carbon, or graphite for dimensional stability), or expanded PTFE (highly conformable microporous structure), these materials are essential for aggressive chemical service.

The common materials used to manufacture rubber gaskets include:

| Material | Temperature Range | Chemical Resistance | Compression Set | Bolt-Load Retention | Weather Resistance |

|---|---|---|---|---|---|

| EPDM | -40°C to +120°C | Excellent (water/steam) | Excellent | High | Excellent |

| Nitrile (NBR) | -30°C to +100°C | Excellent (oils/fuels) | Good | Medium | Poor |

| Silicone | -60°C to +230°C | Good (food-safe) | Excellent | Medium | Excellent |

| Neoprene | -40°C to +100°C | Good (general) | Good | Medium | Good |

| Viton (FKM) | -20°C to +200°C | Excellent (chemicals) | Excellent | High | Excellent |

| Natural Rubber | -50°C to +80°C | Fair | Poor | Medium | Poor |

| SBR | -30°C to +90°C | Fair (water) | Fair | Medium | Fair |

| PTFE | -200°C to +260°C | Universal | Good (with proper design) | Requires high bolt load | Excellent |

To choose the right rubber gasket for your needs, evaluate your application systematically across four critical parameters: fluid compatibility, thermal environment,

mechanical conditions, and regulatory requirements.

The following decision framework guides proper gasket selection:

Catalog every substance the gasket will contact—process fluids, cleaning chemicals, lubricants, and atmospheric exposure. Chemical incompatibility causes swelling, hardening, or dissolution, leading to seal failure. Use chemical resistance charts to match materials: EPDM for water/steam/alkalies, Nitrile for oils/fuels, Viton for aggressive chemicals.

Document minimum, maximum, and typical operating temperatures plus cycling frequency, as temperature affects compression set and mechanical properties. Match material to requirements: Silicone (-60°C to +230°C), EPDM (-40°C to +120°C), Viton (up to 200°C), Natural Rubber (max 80°C). Temperature cycling accelerates aging—consider thermal expansion differentials that can relax bolt loads.

Calculate available bolt load and required gasket seating stress (typically 2-4 MPa for soft gaskets, 10-20 MPa for harder compounds). Match gasket thickness and hardness to surface finish: rough surfaces (>6.3 Ra) need thicker, softer gaskets; smooth surfaces (<3.2 Ra) seal with thinner, harder materials. Select materials with low compression set for dynamic conditions and long-term bolt-load retention.

Ensure materials meet required certifications before engineering analysis: FDA 21 CFR 177.2600 for food processing, NSF 61 for drinking water, USP Class VI for pharmaceuticals, SAE J200 for automotive fuel systems, ASME Section VIII for pressure vessels. Specify exact regulatory requirements (FDA, 3A Sanitary, EU 1935/2004) rather than generic terms like "food-grade."

Balance initial material cost against service life and maintenance frequency—premium materials often justify higher upfront costs through extended service life and reduced downtime. Evaluate replacement complexity for difficult-access locations and consider inventory consolidation to simplify procurement. Assess fabrication requirements: water-jet cutting for prototypes, steel-rule die cutting for volumes above 100 pieces.

Engage experienced gasket engineers to optimize material selection, thickness specification, and flange design based on your complete application requirements. Our technical team identifies potential failure modes (extrusion, blow-out, compression set, chemical attack) and designs preventive measures, eliminating expensive trial-and-error testing.

Our rubber gaskets serve critical sealing functions across the following industries:

EPDM gaskets seal threaded connections, flange joints, and fixtures in hot water heaters, faucet assemblies, and pressure-regulating valves. NSF 61-certified materials ensure drinking water safety while preventing costly water damage and ensuring code compliance.

Nitrile gaskets seal oil pans, valve covers, and fuel systems, resisting motor oil and engine heat, while Viton gaskets handle modern ethanol-blend fuels. Proper selection prevents oil leaks and maintains emissions compliance.

Viton and PTFE gaskets resist aggressive acids, solvents, and oxidizers in reactor vessels, heat exchangers, and pipeline flanges. Proper selection prevents catastrophic leaks and environmental contamination in high-pressure chemical services.

FDA-compliant silicone and EPDM gaskets seal mixers, pumps, and filling equipment while withstanding CIP cleaning cycles and thermal sterilization. Smooth non-porous surfaces resist bacterial growth and ensure regulatory compliance.

USP Class VI silicone gaskets meet biocompatibility requirements for reactor vessels, filtration systems, and sterile filling lines. Steam-sterilizable materials withstand autoclaving without leaching contaminants, ensuring product purity and FDA compliance.

Nitrile and Viton gaskets seal wellhead equipment, separation vessels, and pipeline flanges exposed to crude oil, natural gas, and hydrogen sulfide. Specialty compounds resist sour gas service and prevent dangerous hydrocarbon leaks.

EPDM and neoprene gaskets seal refrigerant circuits and equipment housings, resisting refrigerants (R-410A, R-134a) while providing weather resistance. Proper sealing prevents refrigerant leaks and maintains system efficiency.

Neoprene gaskets resist saltwater corrosion in hatch covers, porthole seals, and pump housings while accommodating hull flexing. Applications span commercial vessels, naval ships, and offshore platforms requiring harsh-condition reliability.

EPDM gaskets seal cooling water circuits while Viton handles lubricating oil and fuel systems in steam turbines and auxiliary machinery. Proper gasket performance prevents unplanned outages and maintains generation capacity.

Our rubber gaskets deliver the following features and benefits:

Compresses to fill microscopic surface irregularities, allowing reliable sealing on less-than-perfect finishes up to 6.3 Ra roughness. Reduces machining costs by 30-50% while ensuring leak-free performance.

Elastomeric resilience maintains sealing force during thermal expansion, pressure surges, and vibration, preventing intermittent leaks. Eliminates costly production interruptions and environmental contamination incidents.

Advanced formulations resist oils, fuels, acids, bases, and solvents tailored to specific exposures. Extends service life 5-10x compared to incompatible materials while reducing downtime.

Maintains sealing integrity from cryogenic (-60°C) to high temperatures (+260°C for PTFE), handling full operating envelopes. Eliminates seasonal gasket changes and prevents thermal cycle failures.

Dampens mechanical vibrations, protecting flanges from fatigue cracking and preventing bolt-loosening. Extends equipment life and improves the workplace environment through noise reduction.

Resists permanent deformation under sustained loads, maintaining 80-90% springback and sealing force throughout service life. Prevents slow leaks without requiring routine retorquing maintenance.

Die-cutting and water-jet processes produce complex shapes economically without expensive machining setups. Reduces total cost 60-80% compared to metal gasket alternatives.

Installs quickly without special tools, conforming to irregular surfaces during bolt tightening. Reduces installation labor 70-80% and minimizes maintenance downtime.

To install rubber gaskets properly, follow this systematic procedure to ensure optimal sealing performance and service life:

Remove old gasket material with plastic scrapers. Clean surfaces thoroughly with appropriate solvents and inspect for damage exceeding 0.1mm depth.

Confirm correct material, thickness, and hardness for application. Inspect for tears, voids, or contamination before installation.

Center gasket concentrically on flange with equal edge distance. Apply adhesive sparingly if needed to prevent shifting.

Install all bolts finger-tight, then apply torque in star pattern at 30%, 60%, and 100% stages using calibrated torque wrench.

Allow 4-24 hours relaxation, then pressure test incrementally at 25%, 50%, 75%, and 100%. Inspect edges for extrusion and check for leaks.

If leaks occur, increase torque incrementally. If the gasket extrudes, reduce torque or use a harder material. Consult engineer for recurring failures.

Here are some frequently asked questions about our Rubber Gaskets to help you find the answers you need:

Viton (FKM) offers the broadest chemical resistance for concentrated acids, solvents, and aggressive chemicals. EPDM excels with alkalies and water-based chemicals, Nitrile resists petroleum oils, and PTFE provides near-universal chemical inertness. Always consult chemical resistance charts for your specific chemical and temperature.

EPDM handles hot water to 120°C and steam to 150°C. Nitrile resists motor oils and hydraulic fluids. Viton resists modern ethanol-blended fuels (E10, E15, E85) required for post-2005 automotive systems.

Yes, soft materials (40-60 Shore A) seal at low pressures, harder materials (70-90 Shore A) handle higher pressures. Fiber-reinforced gaskets reach 300 PSI, metal-reinforced elastomer gaskets handle 600+ PSI.

EPDM provides superior UV/ozone resistance for 15-20 years outdoors. Neoprene offers good outdoor durability at lower cost. Natural rubber and standard nitrile crack within 6-12 months in direct sunlight.

Inspect monthly for critical applications, quarterly for standard equipment, and annually for low-pressure systems. Replace if cracks exceed 1mm, compression exceeds 25%, leakage occurs, or hardness changes >10 Shore A points. Service life: 2-3 years harsh service, 5-7 years moderate, 10+ years mild.

Yes, we manufacture to ISO 9001, ASTM D2000, FDA 21 CFR 177.2600, NSF 61, and ASME Section VIII standards. Custom formulations certified through third-party testing with full documentation.

Chemical incompatibility, over/under-compression, thermal degradation, mechanical damage, or aging. Select proper materials from compatibility charts, follow torque specifications, and choose materials with adequate temperature ratings. Proper selection and installation prevent 95% of failures.

Store in a cool (15-25°C), dark, dry environment away from ozone sources, direct sunlight, and chemicals. Keep in original packaging. Shelf life: silicone/fluoroelastomer 10+ years, EPDM/neoprene 5-7 years, nitrile/natural rubber 3-5 years.

It is not recommended for critical applications because gaskets lose springback after initial compression. Never reuse for high-pressure (>50 PSI), hazardous chemicals, or critical safety applications. Replacement cost is trivial compared to the consequences of a leak.

Measure Inside Diameter (ID)—pipe/port opening; Outside Diameter (OD)—bolt circle diameter plus 3-5mm clearance; Thickness—1.5-3mm for standard flanges. Use digital calipers for ±0.1mm precision.

Yes, Silicone to 230°C (260°C intermittent), Viton to 200°C with chemical resistance, EPDM to 120°C (150°C steam), PTFE to 260°C. Standard nitrile and neoprene fail above 100°C.

Harsh service: 2-3 years; moderate service: 5-7 years; mild service: 10+ years. Replace immediately if leaks occur, surface cracking visible, hardness increases >10 Shore A points, or compression exceeds 25%.

"We recently purchased rubber gaskets from Rubber Xperts INC. and were thoroughly impressed with their service. The team demonstrated a high level of professionalism and ensured we received top-quality products. Their assistance throughout the process was invaluable, and they delivered everything on time. We highly recommend Rubber Xperts INC. for their exceptional quality and outstanding customer support."

"Our dairy organization has been partnering with Rubber Xperts INC. for a while now, and we frequently procure silicone dairy hoses from them. Their customer service and engineering team are outstanding, always ensuring we receive the best products and support. This partnership has been a great success, and we highly recommend Rubber Xperts INC. for their professionalism, quality, and reliability."

With years of experience in hydraulic and pneumatic systems, Rubber Xperts INC makes top-quality rubber products like rubber o-rings, rubber seals, rubber pipes, rubber extrusions, rubber gaskets, rubber mounts, rubber hoses, and more.

We cater to various industries such as construction, aviation, agriculture, and marine. Quality is our priority, ensuring you get the best possible experience and product.

Our team can locate any product for you such as Seals, O-Rings, Gaskets, Pipes, Hoses, and more. If you need help finding a very specific product, reach out to us by phone, email, or contact form. If it exists, we'll find it for you.

We're available Monday-Friday

from 8:00 AM to 6:00 PM EST,

and Saturday from 8:00 AM to 12:00 PM EST.

Top-notch customer support from us,

whether it's before or after your purchase.

Buy easily through our website or

just give us a call.

Customize your ordering and packing preferences with our flexible solutions tailored to your needs.