What are rubber D-ring seals? Learn their functionalities, industry uses, installation methods, lifespan factors, benefits, and how they differ from O-ring seals.

Say goodbye to damage and hello to comfort!

Our Sponge & Foam products are ready to protect and provide comfort for your tools.

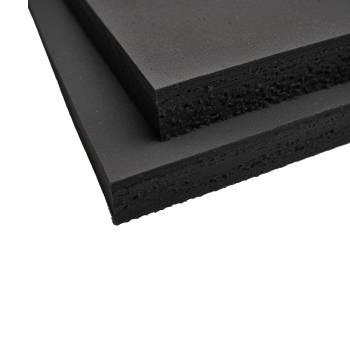

Sponge and Foam are useful materials, each with its own special features and ways of being made. Sponge materials, often from expanded plastic polymers, have lots of tiny holes inside, making them good for cleaning, soaking up liquids, and giving padding or insulation. They come in different strengths and can be artificial or natural, like sea sponges.

Foam is a bigger category, including materials with lots of tiny air pockets. These are made by trapping air bubbles inside liquid or solid stuff during making. Foams can be made from plastics, rubber, or metals and are used a lot in keeping things warm, packaging, padding, and making furniture comfy.

Even though Sponge and Foam are different, they both share some things, like being light, good at soaking up knocks and being able to squish into different shapes. They’re both really handy in lots of jobs across different industries.

Our Sponge and Foam rubber parts bring a host of crucial benefits, making them indispensable across diverse industries. They’re great for cushioning and insulation, offering lightweight solutions adaptable to various uses.

Whether they’re applied in automotive interiors, electronic gadgets, or packaging materials, these components excel at absorbing shocks and resisting impacts. They safeguard goods during transit and machinery operations. Their durability ensures enduring performance even under compression, maintaining effectiveness over time.

With options available in different densities and formulations, you can tailor solutions to meet specific needs. This guarantees optimal performance across a wide range of environments and applications.

Sponge and Foam are commonly found in many appliances.

Here’s where you ca can find Sponge and Foam:

Looking for types of Sponge & Foam tailored to your needs? Browse our catalog and choose which types of Sponge and Foam for various purposes.

Polyurethane Foam is made in various densities and shapes. It's commonly used in mattresses, cushions, and packaging materials. The foam provides good cushioning and support, making it comfortable to sit or sleep on and effective in protecting items during shipping. You can also get it tailored to specific needs, ensuring it fits perfectly in whatever application you need it for.

Polyethylene Foam is known for being lightweight and flexible. It resists moisture and chemicals, which makes it ideal for packaging and insulation. You might use it to protect fragile items during shipping or to insulate pipes and buildings. Its flexibility allows it to conform to the shape of whatever it's protecting, providing a snug fit. Plus, it's easy to handle and cut to size, making it convenient for various uses.

Neoprene Sponge is a synthetic rubber material that's tough and resilient. It resists oil, weather, and UV light, making it suitable for outdoor and harsh environments. These uses benefit from its ability to create a tight seal that keeps out water and other elements. Neoprene Sponge maintains its properties over a wide range of temperatures.

Silicone Foam is a high-performance material that can withstand extreme temperatures, both hot and cold. The foam provides excellent sealing capabilities, ensuring that components remain protected from leaks and contaminants. Its flexibility allows it to conform to complex shapes, creating a tight seal.

EVA (Ethylene-Vinyl Acetate) Foam is soft, flexible, and lightweight. It's widely used in products where comfort and impact resistance are important, such as sports equipment padding, shoe insoles, and children's toys. The foam is effective at absorbing shocks, which helps protect you from impacts. It's also easy to clean and maintain, and it doesn’t absorb water, making it suitable for outdoor and damp environments.

PVC/Nitrile Foam is a blend of polyvinyl chloride and nitrile rubber, known for its resistance to oils, fuels, and chemicals. The foam creates an effective barrier against harsh fluids and environmental elements, protecting machinery and equipment. It's also durable and maintains its properties over time, which means it doesn’t break down easily.

Closed Cell Foam is designed to resist water, making it buoyant and suitable for flotation devices and marine applications. Its structure keeps water out, so it remains lightweight and doesn't absorb moisture. The foam is strong and durable, providing long-term performance in wet or damp environments. Additionally, closed cell foam offers good insulation properties, making it useful for thermal insulation in various settings.

Do you have questions about rubber bellows? Find the answers here. If that is still not enough, contact our customer service!

Silicone Foam typically has a maximum temperature resistance ranging from -60°C to 250°C (-76°F to 482°F), depending on the specific formulation and application requirements. Some specialty silicone foams can withstand even higher temperatures.

The density of Polyurethane Foam affects its firmness, support, and durability. Higher density foams tend to be firmer and offer better support, making them suitable for applications requiring more robust cushioning, such as mattresses and automotive seating. Lower density foams are softer and more lightweight, offering greater comfort but may not provide as much support for heavier loads.

PVC/Nitrile Foam is commonly used in automotive applications such as door seals, weatherstripping, and gaskets. Its resistance to oil, fuel, and chemicals, combined with its excellent sealing properties, makes it well-suited for these sealing applications, helping to prevent leaks and maintain vehicle integrity.

Yes, Neoprene Foam is often used in marine environments due to its excellent resistance to weather, ozone, and UV exposure. It is commonly used for marine gaskets, seals, and weatherstripping to provide reliable sealing against moisture and saltwater ingress, helping to protect marine equipment and structures from corrosion and deterioration.

FKM/Viton Foam is widely used in industries such as automotive, aerospace, chemical processing, and oil and gas, where exposure to extreme temperatures, aggressive chemicals, fuels, and oils is common. It is used for sealing applications such as gaskets, O-rings, and seals, providing reliable sealing against leaks and contamination in demanding environments.

With years of experience in hydraulic and pneumatic systems, Rubber Xperts INC makes top-quality rubber products like rubber o-rings, rubber seals, rubber pipes, rubber extrusions, rubber gaskets, rubber mounts, rubber hoses, and more.

We cater to various industries such as construction, aviation, agriculture, and marine. Quality is our priority, ensuring you get the best possible experience and product.

Our team can locate any product for you such as Seals, O-Rings, Gaskets, Pipes, Hoses, and more. If you need help finding a very specific product, reach out to us by phone, email, or contact form. If it exists, we'll find it for you.

We're available Monday-Friday

from 8:00 AM to 6:00 PM EST,

and Saturday from 8:00 AM to 12:00 PM EST.

Top-notch customer support from us,

whether it's before or after your purchase.

Buy easily through our website or

just give us a call.

Customize your ordering and packing preferences with our flexible solutions tailored to your needs.