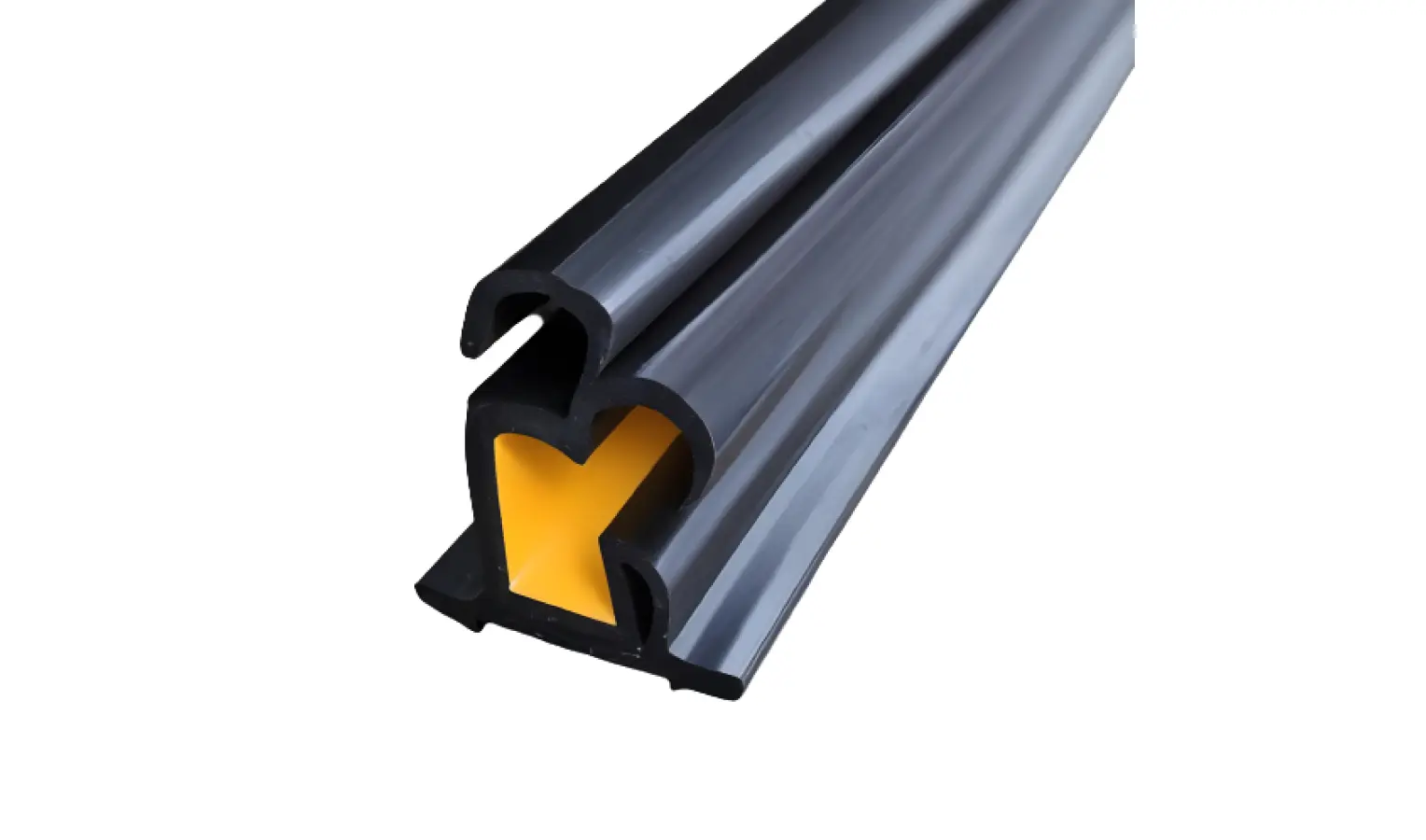

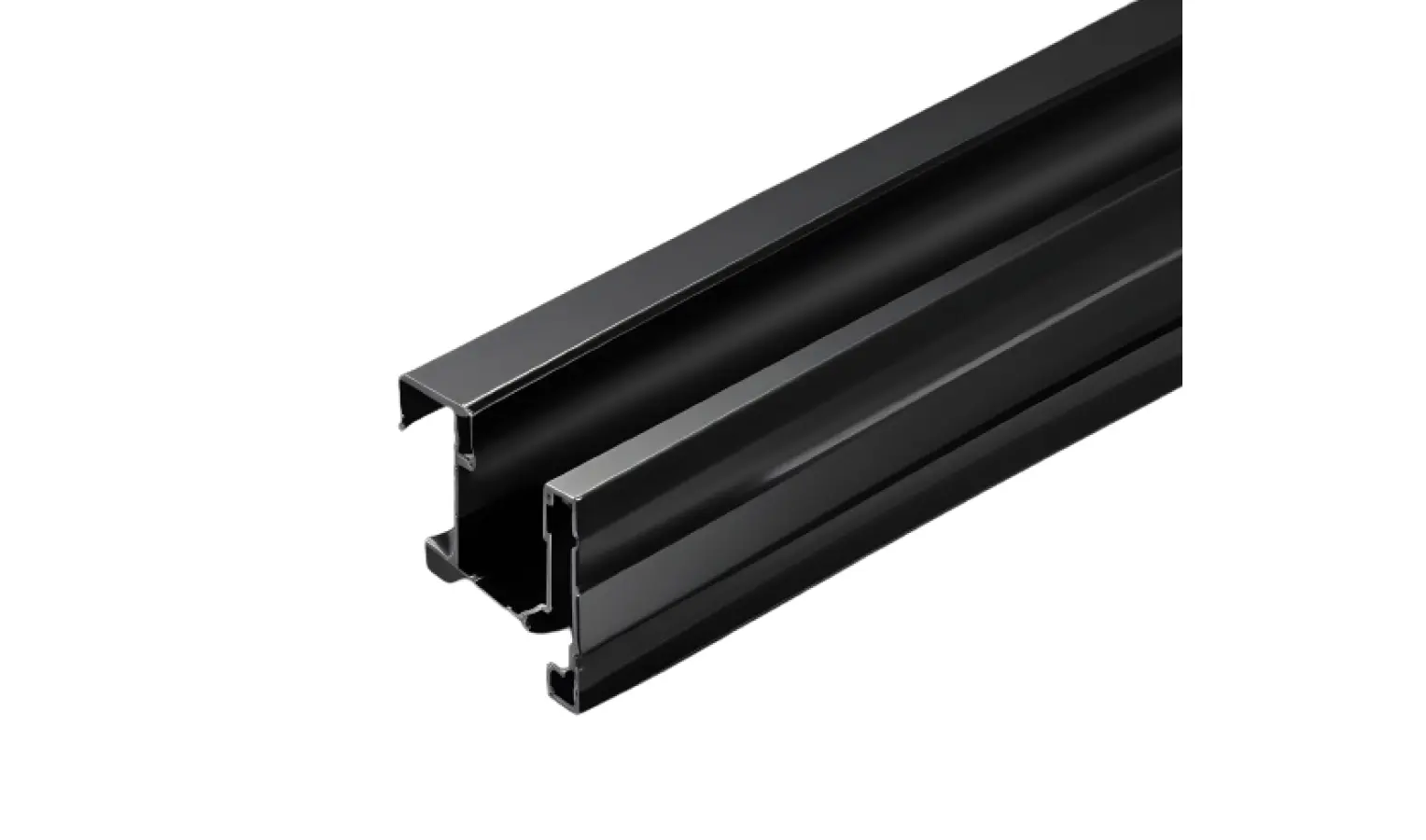

Rubber D-Ring Seals: Functionality, Material Selection, Industry Uses, Installation Techniques, And Longevity

What are rubber D-ring seals? Learn their functionalities, industry uses, installation methods, lifespan factors, benefits, and how they differ from O-ring seals.