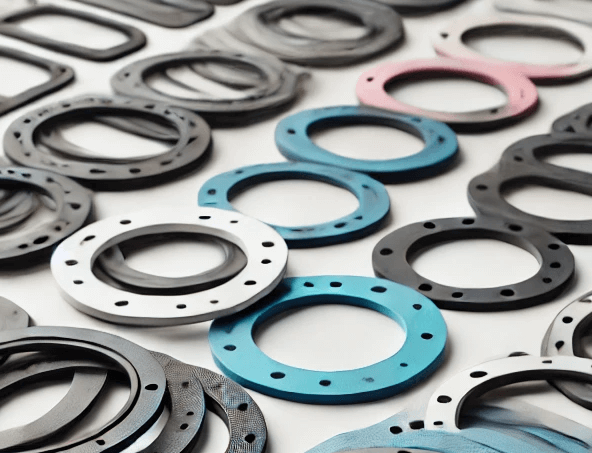

Rubber flat gaskets refer to sealing components designed to create a reliable barrier between flat mating surfaces in static applications. Their versatility and adaptability make them vital in systems requiring secure and leak-proof seals.

The types of rubber flat gaskets include neoprene for oil resistance, EPDM for weather and ozone durability, nitrile for fuel and chemical applications, and silicone for high-temperature resilience.

According to a study by Singh et al. titled “Performance Analysis of Elastomeric Seals in High-Pressure Environments,” published in Industrial Materials Research (2020), EPDM gaskets exhibited superior resistance to environmental degradation, maintaining 75% of tensile strength after 1,000 hours of UV exposure.

Applications of rubber flat gaskets span industries such as plumbing, automotive, and manufacturing, where they seal flat surfaces like flanges, joints, and covers.

The advantages of rubber flat gaskets include flexibility, compressibility, and resistance to environmental factors like temperature fluctuations, abrasion, and chemical exposure. Their ability to adjust to uneven surfaces ensures effective sealing in critical applications.

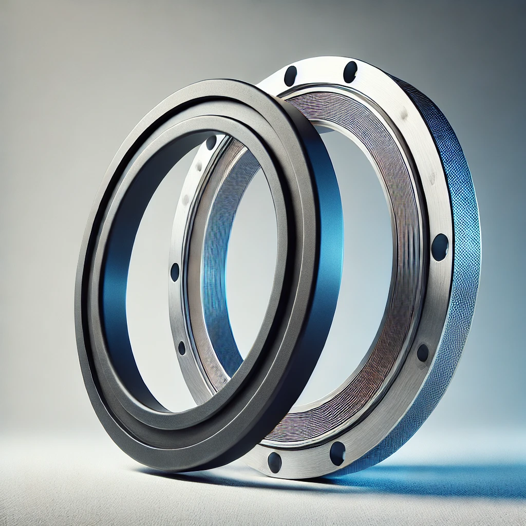

The installation process of a rubber flat gasket involves cleaning the surfaces, aligning the gasket, and applying uniform force across the compression layer to achieve a leak-proof seal. Proper alignment of bolt-hole patterns and flat sealing rings is key for preventing misalignment and maintaining performance.

Common issues with rubber flat gaskets include material degradation, incorrect sizing, or misalignment during installation, which lead to sealing failure. Best practices for maintaining rubber flat gaskets include using reinforced rubber gaskets and conducting regular inspections.

What Are Rubber Flat Gaskets?

Flat rubber gaskets are sealing components designed to create a secure and leak-proof barrier between two surfaces. They are primarily used in flanged joints, pressure vessels, pipelines, and other industrial equipment to prevent the leakage of fluids, gases, or solids under varying conditions.

Flat rubber gaskets are made from elastomeric materials like Buna-N, EPDM, silicone, and neoprene. These materials provide excellent sealing properties due to their flexibility, compression, and resilience.

The gasket is positioned between two mating surfaces, compressing under pressure to fill surface irregularities, thereby ensuring a tight seal. Its common applications include automotive engines, household plumbing, HVAC systems, and chemical processing plants.

According to a study by Han et al. titled “Numerical Simulation of Assembly Process and Sealing Reliability of T-Rubber Gasket Pipe Joints,” published in Sustainability (2023), rubber gaskets exhibit superior adaptability to various deformations, making them essential for sealing joints in pipelines under dynamic environmental conditions.

What Are The Different Types Of Rubber Flat Gaskets?

The different types of rubber flat gaskets are listed below:

- Buna-N/Nitrile Gaskets

- EPDM Gaskets

- Neoprene Gaskets

- Silicone Gaskets

- Viton Gaskets

- Chloroprene Gaskets

- Natural Rubber Gaskets

- PTFE-Coated Rubber Gaskets

Buna-N/Nitrile Gaskets

Buna-N/Nitrile gaskets are known for their excellent resistance to oils and fuels, making them ideal for automotive and industrial applications. Buna-N, also known as nitrile rubber, is a synthetic elastomer designed to withstand exposure to petroleum-based substances. It is a preferred choice for sealing applications in environments involving oils, fuels, and chemicals.

The material offers superior durability, flexibility, and resistance to abrasion, ensuring reliable performance in demanding conditions.

Buna-N gaskets are widely used in fuel pumps, hydraulic equipment, and oil and gas pipelines due to their resilience to oil and gasoline contact while maintaining strong sealing properties under varying pressures and temperatures.

EPDM Gaskets

EPDM gaskets are widely used in applications requiring resistance to ozone, weathering, and high-temperature variations. They are made from EPDM, or Ethylene Propylene Diene Monomer, a synthetic rubber material specifically engineered for durability in harsh outdoor environments.

Their resistance to ultraviolet rays, ozone, and aging makes them an excellent choice for sealing applications in HVAC systems, household plumbing, and chemical processing plants.

EPDM gaskets also provide excellent thermal stability and flexibility, making them practical for use in automotive cooling systems, refrigeration units, and outdoor electrical enclosures where temperature fluctuations and environmental exposure are relevant factors.

Neoprene Gaskets

Neoprene gaskets are valued for their versatility in sealing applications, offering protection against oil and weathering. They are made with neoprene rubber, a synthetic material known for its balanced properties, including resistance to moderate oil exposure, ozone, and weathering.

These characteristics make it a reliable choice for applications in HVAC systems, refrigeration units, and moderate-duty industrial environments.

Neoprene gaskets also provide good flexibility and durability, ensuring consistent sealing performance in environments with varying temperatures and pressures, such as in household plumbing and general-purpose industrial equipment.

Silicone Gaskets

Silicone gaskets are ideal for applications requiring high-temperature resistance and non-reactivity in sensitive environments. They are made from silicone rubber, a premium elastomer known for its exceptional thermal stability. They maintain performance in extreme temperatures ranging from -75°F to 450°F

The silicone’s chemical inertness and non-toxic properties make it highly suitable for use in food processing, pharmaceutical production, and medical devices, where safety and compliance with FDA standards are critical.

Silicone gaskets are also resistant to aging, UV exposure, and weathering, ensuring long-lasting and reliable sealing performance in demanding industrial and hygienic environments.

Viton Gaskets

Viton gaskets are essential in high-performance applications requiring resistance to extreme temperatures and aggressive chemicals. Viton, also known as FKM, is a high-performance fluoroelastomer praised for its superior chemical resistance, thermal stability, and durability.

Viton gaskets withstand temperatures up to 400°F and exposure to fuels, oils, and corrosive chemicals, making them the best choice for important sealing applications. Viton gaskets are widely used in aerospace equipment, automotive engines, and chemical processing plants, where reliability under extreme conditions is necessary for operational safety and efficiency.

Chloroprene Gaskets

Chloroprene gaskets, commonly referred to as neoprene, are widely used in industrial applications due to their resistance to oil, ozone, and weathering. This synthetic rubber is known for its versatility and robust performance in sealing applications exposed to harsh environmental conditions.

Its balanced resistance to moderate chemicals, oil, and UV radiation makes it a reliable choice for outdoor use in HVAC systems, marine equipment, and general industrial sealing.

Chloroprene gaskets are also valued for their durability and flexibility, making them suitable for both industrial and commercial applications where consistent sealing performance is imperative.

Natural Rubber Gaskets

Natural rubber gaskets are used in applications that require a balance of flexibility and moderate sealing capabilities. Natural rubber, derived from latex, is valued for its excellent elasticity, wear resistance, and ability to provide adequate sealing in non-extreme environments.

While it is less resistant to oils and high temperatures compared to synthetic alternatives, its cost-effectiveness and durability make it suitable for automotive components, construction materials, and general-purpose industrial sealing applications.

Natural rubber gaskets are commonly used in flanged joints, vibration dampening, and other situations where flexibility and wear resistance are necessary.

PTFE-Coated Rubber Gaskets

PTFE-coated rubber gaskets are ideal for chemical processing and sealing in harsh chemical environments. This material integrates the flexibility and resilience of rubber with the non-stick, high chemical resistance properties of PTFE (polytetrafluoroethylene), commonly known as Teflon.

The coating enhances the gasket’s resistance to corrosive chemicals, extreme temperatures, and abrasion while maintaining the rubber’s sealing performance.

PTFE-coated rubber gaskets are extensively used in industries like chemical processing, pharmaceuticals, and oil and gas, where a combination of durability, chemical resistance, and reliable sealing is needed.

What Materials Are Used For Rubber Flat Gaskets?

The materials commonly used for rubber flat gaskets include Nitrile (Buna-N), EPDM, Neoprene, Silicone, Viton, Chloroprene, Natural Rubber, and PTFE (Teflon). The material of a rubber flat gasket is necessary for ensuring performance under specific environmental conditions and stress factors.

The material used for rubber flat gaskets determines the gasket’s resistance to temperature extremes, chemical exposure, and mechanical stress.

Each material offers unique properties; for instance, Nitrile excels in oil resistance, Silicone withstands high temperatures, and PTFE provides superior chemical inertness.

Proper material selection helps the gasket perform reliably in applications ranging from chemical processing to automotive systems.

Nitrile (Buna-N)

Nitrile rubber offers exceptional resistance to oils, fuels, and lubricants, making it a preferred material for demanding industrial environments. It is also known for its durability and flexibility and is highly effective in sealing applications where exposure to petroleum-based substances is prevalent.

This material is widely used in the automotive and aviation industries for components like fuel hoses, oil seals, and gaskets due to its ability to maintain performance under high-pressure and temperature conditions.

Its robustness also makes it suitable for hydraulic equipment, fuel systems, and other industrial applications requiring resilience to harsh chemical exposure.

EPDM

EPDM, or Ethylene Propylene Diene Monomer, is a synthetic elastomer that maintains its flexibility and performance over prolonged exposure to UV rays, heat, and environmental factors.

EPDM rubber is known for its outstanding resistance to aging, ozone, and extreme weather conditions, making it a reliable material for outdoor sealing applications.

This makes it an ideal choice for applications in plumbing systems, roofing membranes, and outdoor sealing tasks where durability and weather resistance are necessary.

Its thermal stability and resilience further increase its suitability for HVAC systems, automotive weather stripping, and electrical enclosures.

Silicone

EPDM rubber is known for its outstanding resistance to aging, ozone, and extreme weather conditions, making it a reliable material for outdoor sealing applications.

EPDM, or Ethylene Propylene Diene Monomer, is a synthetic elastomer that maintains its flexibility and performance over prolonged exposure to UV rays, heat, and environmental factors.

EPDM rubber is an ideal choice for applications in plumbing systems, roofing membranes, and outdoor sealing tasks where durability and weather resistance are essential. Its thermal stability and resilience further enhance its suitability for HVAC systems, automotive weather stripping, and electrical enclosures.

Neoprene

Neoprene rubber is a versatile material offering resistance to oil, ozone, and moderate chemicals, making it suitable for general-purpose sealing applications. Its durability and weather resistance provide reliable performance in HVAC systems, refrigeration units, and industrial equipment exposed to environmental factors.

Neoprene gaskets are frequently used in marine applications, electrical enclosures, and moderate-duty sealing tasks where a balance of flexibility and resilience is required.

Viton

Viton rubber is a premium material known for its exceptional chemical resistance and thermal stability, making it indispensable for high-performance sealing.

It is commonly used in aerospace, automotive, and chemical processing industries. Viton material excels in environments exposed to aggressive fuels, oils, and corrosive chemicals. Its ability to withstand temperatures up to 400°F ensures excellent performance in extreme operating conditions.

Chloroprene

Chloroprene rubber is a durable material with resistance to oil, weathering, and ozone, making it perfect for outdoor and industrial sealing applications.

Chloroprene material is frequently used in HVAC systems, marine equipment, and general industrial environments due to the need for exposure to environmental stressors. Its balanced properties make it a reliable choice for both commercial and industrial uses.

Natural Rubber

Natural rubber is a flexible and wear-resistant material suitable for applications requiring moderate sealing performance. It is commonly used in the automotive and construction industries for vibration dampening, flanged joints, and general-purpose sealing tasks.

While it lacks the oil and chemical resistance of synthetic alternatives, its cost-effectiveness and durability make it a practical choice for non-extreme environments.

PTFE-Coated (Teflon) Rubber

PTFE-coated rubber combines rubber’s flexibility with PTFE’s chemical resistance and non-stick properties, making it suitable for harsh chemical environments.

This gasket material is widely used in chemical processing plants, pharmaceuticals, and oil and gas industries, where a robust and chemically inert sealing solution is needed. The PTFE coating enhances durability while maintaining rubber’s necessary sealing characteristics.

What Are The Applications Of Rubber Flat Gaskets?

The applications of rubber flat gaskets are listed below:

- Automotive

- Aerospace

- Plumbing

- HVAC

- Oil & Gas

- Food & Beverage

- Pharmaceutical

- Chemical Processing

Automotive

In automotive applications, rubber flat gaskets are used in engines, fuel systems, and transmissions to prevent fluid leakage and ensure performance.

These gaskets are required in sealing components such as oil pans, cylinder heads, and fuel pumps because they maintain the integrity of the systems under high temperatures and pressures.

Nitrile gaskets are commonly used in fuel systems due to their resistance to oils and fuels, while silicone gaskets are preferred in engines for their ability to withstand extreme temperatures.

Rubber flat gaskets increase the reliability and efficiency of automotive systems by providing durable and flexible sealing solutions.

Aerospace

Aerospace applications require rubber flat gaskets that withstand extreme temperatures and chemical exposure. These requirements make gasket materials like Viton ideal.

These gaskets are needed in sealing fuel systems, hydraulic lines, and engine components, ensuring reliability in harsh operating environments.

Viton gaskets are particularly suited for aerospace applications due to their exceptional thermal stability and resistance to aggressive fuels and lubricants.

Rubber flat gaskets contribute to the safety and efficiency of aerospace systems by maintaining a secure seal under high pressure and temperature variations.

Plumbing

In plumbing, rubber flat gaskets ensure leak-proof seals in joints, pipes, and fittings, especially under high-pressure conditions. These gaskets are paired with rubber seals to provide a reliable barrier and prevent water and gas leakage in household and industrial systems.

Rubber flat gaskets are commonly used in flanged pipe connections and threaded fittings. They are chosen for their flexibility and resistance to wear.

EPDM gaskets are particularly effective in plumbing applications due to their durability and resistance to weathering and water exposure. They provide long-lasting performance in both indoor and outdoor environments.

HVAC

Rubber flat gaskets are commonly used in HVAC systems to create airtight seals in ducts, preventing air leaks and improving energy efficiency. These gaskets are necessary for maintaining proper airflow and reducing energy loss in heating, ventilation, and air conditioning systems.

EPDM and neoprene gaskets are frequently utilized due to their excellent resistance to weathering, temperature fluctuations, and environmental stress.

Rubber flat gaskets increase the overall performance and longevity of HVAC systems by providing reliable sealing in ductwork and equipment connections.

Oil & Gas

In the oil and gas industry, rubber flat gaskets play a key role in preventing leaks in high-pressure pipelines and equipment. These gaskets are used in valves, pumps, and flanged joints to ensure a secure seal under demanding conditions involving high temperatures, pressures, and exposure to corrosive substances.

Materials like nitrile and Viton are commonly chosen for their resistance to fuels, oils, and chemicals, providing durability and reliability. Rubber flat gaskets contribute to the safe and efficient operation of oil and gas systems by maintaining integrity and preventing environmental contamination.

Food & Beverage

In food processing, rubber flat gaskets made from silicone or EPDM are used to prevent contamination and ensure clean sealing in production equipment. These gaskets are necessary for applications requiring hygienic sealing, such as in tanks, pipelines, and processing machinery.

Silicone gaskets are particularly effective in high-temperature operations. EPDM gaskets also provide excellent resistance to water and steam, ensuring reliable performance in the stringent conditions of the food and beverage industry.

Their non-toxic, non-reactive, and FDA-compliant properties make them ideal for maintaining food safety and preventing bacterial growth.

Pharmaceutical

Rubber flat gaskets in the pharmaceutical industry ensure the containment of sensitive substances, providing tight seals in mixing, filling, and packaging equipment. These gaskets are needed to maintain sterile conditions and prevent cross-contamination in pharmaceutical processes.

Materials like silicone and PTFE-coated rubber are widely used for their non-reactive, non-toxic, and FDA-compliant properties.

Rubber flat gaskets are important in equipment such as reactors, pipelines, and storage tanks, where cleanliness and chemical resistance are relevant for ensuring product integrity and compliance with industry standards.

Chemical Processing

In chemical processing, rubber flat gaskets made from materials like PTFE are used to withstand exposure to aggressive chemicals and ensure leak-proof seals.

These gaskets are relevant in maintaining safety and operational efficiency in environments involving corrosive substances and extreme temperatures.

PTFE-coated rubber and Viton gaskets are particularly suitable for chemical reactors, pipelines, and storage tanks due to their high chemical resistance and durability.

Rubber flat gaskets prevent leaks, reduce downtime, and ensure the integrity of equipment in demanding chemical processing plants.

What Are The Advantages Of Rubber Flat Gaskets?

The advantages of rubber flat gaskets are listed below:

- Durability

- Flexibility

- Chemical Resistance

- Temperature Tolerance

- Easy Installation

- Cost-Effectiveness

Durability

Rubber flat gaskets are known for their durability, withstanding mechanical stress and temperature fluctuations over extended periods.

Their robust construction and resistance to wear allow them to maintain a reliable seal even under challenging operating conditions. Rubber flat gasket durability is increased with the use of rubber seals.

This durability makes rubber materials ideal for high-pressure systems, industrial pipelines, and automotive engines, where consistent performance and longevity are necessary.

Rubber’s abrasion resistance and elasticity also contribute to their ability to endure repetitive cycles of compression and recovery, ensuring their functionality over time.

Flexibility

Rubber flat gaskets’ flexibility allows them to conform to irregular surfaces, ensuring a reliable and tight seal. This adaptability makes them highly effective in applications where surface imperfections or misalignments compromise sealing performance.

Their elasticity enables them to maintain consistent pressure across contact points, even in dynamic environments with vibration or movement.

Rubber flat gaskets are widely used in automotive engines, plumbing systems, and industrial equipment, where their ability to accommodate varying surface conditions increases overall sealing efficiency.

Chemical Resistance

Rubber flat gaskets made from materials like Viton and EPDM provide outstanding resistance to harsh chemicals and solvents. This chemical resistance makes them ideal for use in corrosive environments such as chemical processing plants, oil and gas pipelines, and pharmaceutical equipment.

These materials’ ability to withstand exposure to acids, alkalis, and fuels ensures long-term sealing performance and safety.

Rubber gaskets improve system reliability and durability by preventing degradation from chemical contact.

Temperature Tolerance

Rubber flat gaskets, especially those made from silicone and Viton, offer excellent performance in extreme temperature environments, from cryogenic to high-heat applications.

Silicone gaskets maintain their flexibility and sealing properties in temperatures ranging from -75°F to 450°F, making them suitable for high-temperature industrial processes and refrigeration systems.

Similarly, Viton gaskets excel in applications involving sustained exposure to heat and aggressive chemicals, withstanding temperatures up to 400°F.

This broad temperature tolerance boosts the reliability of rubber flat gaskets in aerospace, automotive, and chemical processing industries, where thermal stability is relevant.

Easy Installation

Rubber flat gaskets are lightweight and flexible, making them easy to install in a variety of sealing applications. Their adaptability allows them to fit securely into flanged joints, pipes, and equipment with minimal effort.

Customizable shapes, achieved through methods like die cutting and waterjet cutting, ensure a precise fit for specific requirements, reducing installation time and improving sealing efficiency.

This ease of installation makes rubber flat gaskets a perfect choice for industries such as plumbing, HVAC, and automotive, where quick and reliable sealing solutions are required.

Cost-Effectiveness

Rubber flat gaskets are a cost-effective solution for sealing applications. They provide reliable performance at a fraction of the cost of metal or composite alternatives.

Their affordability, combined with durability and ease of installation, reduces overall maintenance and operational costs.

Rubber materials like EPDM and nitrile offer excellent performance in diverse environments without the higher expenses associated with specialized sealing materials.

This cost-effectiveness makes rubber flat gaskets a preferred choice in industries like automotive, plumbing, and chemical processing, where budget considerations are balanced with reliable sealing performance.

How To Install Rubber Flat Gaskets?

The steps for installing rubber flat gaskets are listed below:

- Clean the surfaces

- Prepare the gasket

- Position the gasket

- Tighten the flange or joint

- Inspect the installation

Clean The Surfaces

Before installing a rubber flat gasket, it is important to clean the mating surfaces to remove any debris, dirt, or oil that compromises the seal. Surface contaminants create gaps or irregularities that prevent the gasket from forming a tight seal, leading to potential leaks.

Cleaning ensures that the gasket sits flush against the surface, maximizing its sealing efficiency and prolonging its lifespan.

Proper surface preparation is relevant for maintaining the reliability of the sealing system in applications like pipelines, HVAC systems, and automotive components.

Prepare The Gasket

Ensure the rubber flat gasket is appropriately sized and matches the dimensions of the flange or joint before installation. Verifying the gasket’s compatibility with the specific application prevents misalignment and ensures optimal sealing performance.

Inspect the gasket for any damage, such as cracks or deformities, which compromise its effectiveness. Check the custom-cut gaskets for precision in bolt-hole patterns and central openings to ensure a proper fit. Proper preparation of the gasket is necessary to achieve a reliable and leak-proof seal in applications.

Position The Gasket

Carefully position the gasket in the proper location, ensuring it is evenly distributed around the entire flange or joint. Align the gasket surface with the flat seal face of the flange, making sure the bolt-hole pattern matches precisely to avoid misalignment during tightening.

The sealing edge of the gasket needs to be in complete contact with the compression layer of the joint to create a uniform seal. Proper positioning prevents gaps or uneven compression, ensuring the gasket performs properly under operating conditions.

Tighten The Flange Or Joint

Tighten the flange or joint evenly, following a crosswise pattern to apply uniform pressure on the gasket and ensure a tight seal. This method prevents over-compression or uneven stress on the gasket surface, which damages the sealing edge or compromises the integrity of the flat seal face.

Gradual and balanced tightening ensures the bolt-hole pattern aligns correctly and the gasket’s reinforcement layer maintains its structural integrity. Proper tightening is key to achieving a reliable seal and prolonging the gasket’s lifespan under compression.

Inspect The Installation

After installation, inspect the gasket for any signs of improper sealing or damage and test the system for leaks to confirm the gasket’s performance. Make sure the gasket surface is evenly compressed and the sealing edge aligns perfectly with the joint.

Check for any visible gaps, misalignment, or over-compression that will compromise the seal. Inspect the bolt-hole pattern and reinforcement layer to verify proper alignment and pressure distribution.

Conduct a pressure or leak test to validate the gasket’s effectiveness and ensure the installation meets operational requirements and reliability.

What Are The Key Advantages Of Rubber Flat Gaskets Compared To Metal Gaskets?

The key advantages of rubber flat gaskets compared to metal gaskets are their flexibility and cost-effectiveness, especially in low-pressure sealing applications.

Unlike metal gaskets, which require precise machining and higher installation torque, rubber flat gaskets offer ease of installation due to their elastomeric flat seals and planar rubber seals.

The elastomeric flat seas and planar rubber seals conform to surface irregularities and reduce the need for high clamping force. Their flexibility allows them to maintain a reliable seal even under fluctuating pressure conditions.

Rubber gaskets also exhibit low friction and are non-toxic, tasteless, odorless, and easy to clean, making them suitable for industries like food processing and pharmaceuticals.

Rubber gaskets outperform metal alternatives in environments requiring hygiene and chemical resistance, mainly because they are resistant to mold and bacterial growth and resilient to oil, gasoline, and fluids.

According to a study by Wróbel and Walczak titled “Load Condition Analysis of Pipe Flange Connection with Gasket Flat Gasket and Loose Clamping Rings,” published in the Journal of Achievements in Materials and Manufacturing Engineering (2022), rubber gaskets demonstrated a 40% lower failure rate in dynamic systems compared to metal gaskets due to their enhanced flexibility and adaptability to variable conditions.

In What Industries Are Rubber Flat Gaskets Most Commonly Used?

Rubber flat gaskets are widely used in industries such as automotive, aerospace, and oil & gas due to their adaptability and sealing performance.

In the automotive sector, they are necessary for sealing components like fuel pumps, hydraulic equipment, and pipelines, providing durability and resilience to oil, gasoline, and fluids.

Aerospace applications require gaskets with superior chemical resistance and thermal stability, such as those used in hydraulic systems and electrical enclosures, where operational reliability under extreme conditions is required.

In food processing industries, FDA-compliant rubber gaskets, like silicone ones, ensure safe, non-toxic, and hygienic sealing for pipelines and HVAC systems.

Pharmaceutical industries also depend on these gaskets for sealing sensitive equipment due to their ease of cleaning and resistance to mold and bacterial growth.

In the oil and gas industry, rubber flat gaskets provide vital sealing solutions for high-pressure pipelines and chemical processing systems. In plumbing systems, they prevent leakage in joints and fittings under diverse conditions.

These applications make rubber gaskets indispensable across multiple industries.

How Do Environmental Factors Affect The Performance Of Rubber Flat Gaskets?

Environmental factors affect the performance of rubber flat gaskets by degrading their performance. Extreme temperatures, chemical exposure, and weathering influence rubber flat gaskets, requiring careful material selection.

High-temperature environments need materials like Viton, which provides exceptional thermal resistance up to 400°F. At the same time, EPDM is favored for its superior weather resistance and durability under prolonged UV and ozone exposure.

Chemical exposure degrades certain elastomers, but rubber sheet gaskets made from PTFE-coated materials or silicone resist mold, bacterial growth, and harsh chemicals, providing long-term performance in industrial and hygienic applications.

Abrasion resistance is another factor, especially in dynamic environments like pipelines and hydraulic systems, where gaskets face mechanical wear.

According to a study by Zhao et al. titled “Thermal and Chemical Stability of Elastomeric Seals in High-Stress Applications,” published in Materials Engineering Journal (2019), EPDM gaskets exhibited a 75% retention in tensile strength after 1,000 hours of UV and ozone exposure, compared to a 50% retention for standard rubber materials.

This data emphasizes the importance of selecting weather-resistant and durable materials to increase gasket performance in demanding environmental conditions.

Can Rubber Flat Gaskets Be Reused After Disassembly?

Yes, rubber flat gaskets can be reused after disassembly. However, this is not advisable due to potential deformation and loss of sealing integrity after initial use. When subjected to the pressure required for sealing, the compression layer of the gasket undergoes permanent deformation, especially in high-pressure flat gaskets.

Reinforced rubber gaskets or rubber flange gaskets retain some structural integrity, but their ability to provide a reliable seal diminishes with reuse.

Custom profiles and flat sealing rings, specially designed for unique applications, also experience wear and compression sets that compromise their effectiveness. Always replace the rubber flat gasket after disassembly to maintain consistent optimal performance, especially in critical systems.

Are Rubber Flat Gaskets Suitable For High-Temperature Applications?

Yes, rubber flat gaskets made from materials like Viton and silicone are suitable for high-temperature applications, while others degrade under heat. These gaskets exhibit exceptional high-temperature resistance, with Viton gaskets performing reliably in temperatures up to 400°F and silicone rubber gaskets maintaining their sealing properties from -75°F to 450°F.

EPDM gaskets also offer strong thermal resistance for moderate-temperature applications, making them versatile for both industrial and food-grade applications. Custom-cut flat gaskets crafted from FDA-approved materials like silicone provide compliance in high-temperature food processing and pharmaceutical systems where hygiene and thermal stability are imperative.

According to a study by Patel et al. titled “Thermal Stability and Mechanical Integrity of Elastomeric Seals in Extreme Environments,” published in the Journal of Polymer Science (2021), silicone gaskets retained 95% of their compression set resistance after 1,500 hours at 400°F, while standard rubber gaskets showed significant degradation under similar conditions.

This data shows the suitability of Viton and silicone for applications requiring durability in extreme heat environments.