When you work with machines, you know how important it is to keep everything running smoothly.

Leaks and seal problems can cause downtime and headaches.

But how do you choose the right seal for the job?

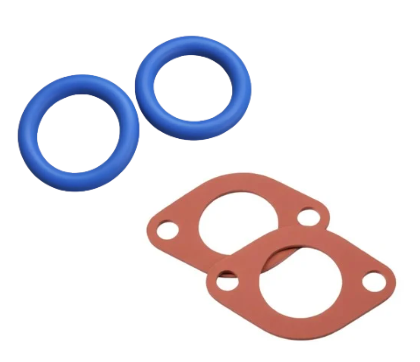

That’s why, knowing the difference between various rubber seals, such as rubber gaskets vs. rubber o-rings, is crucial for your work.

In this article, we’ll help you make the right choice so you can keep your equipment in top shape and avoid unnecessary issues.

Find the top rubber o-rings for your industry needs today! Contact us if you need specific customizations with the materials, colors, and more!

Differences Between Rubber Gaskets vs. Rubber O-Rings

Imagine you’re in the middle of a busy workday, and one of your machines starts leaking.

You need a quick fix, but you also don’t want to ruin the machine with DIY methods.

Selecting an incorrect seal, like confusing rubber gaskets vs. rubber o-rings, can lead to further leaks and downtime.

Understanding the distinction helps address issues efficiently, saving time and frustration.

Type of Seal: Static vs. Dynamic

Rubber gaskets vs. rubber o-rings serve different purposes based on whether machinery parts move.

If the parts are not moving and stay fixed together, like two plates bolted together, you need a static seal.

In this case, a rubber gasket is the best choice because it fits well between flat surfaces that don’t move.

On the other hand, if the parts of your machine are moving, like a piston inside a cylinder, you need a dynamic seal.

For moving parts, a rubber o-ring is better. Many types of rubber o-rings can compress and adjust to the movement.

They keep a good seal even when parts are moving.

Shape and Surface

The decision between rubber gaskets vs. rubber o-rings also hinges on the parts’ shape and surface.

When it comes to sealing flat, large areas on your machine, there are various rubber gasket types available to perfectly meet your needs.

Gaskets can be cut into different shapes and sizes to fit flat surfaces perfectly.

However, if the surfaces have grooves or are not flat, like a circular groove in a pump, a rubber o-ring is the way to go.

O-rings are designed to fit into grooves and can handle more complex shapes.

They are flexible and can adjust to fit the groove’s shape, providing a reliable seal.

Pressure Conditions

The operational pressure of machinery is a critical factor when comparing rubber gaskets vs. rubber o-rings.

If your machine operates under high pressure, a rubber o-ring is the better choice.

O-rings can handle high-pressure environments because their circular shape allows them to compress and form a tight seal.

If the pressure is low to moderate, a rubber gasket will work well.

Gaskets are suitable for less extreme pressure conditions and can still provide a good seal.

Temperature Range

Both rubber gaskets and rubber o-rings come in materials suited for various temperature ranges.

The choice between rubber gaskets vs. rubber o-rings may depend on whether your machinery operates at extreme temperatures.

So, you need a material compatible with those conditions.

Always check the material compatibility with the temperature range.

If your machine operates in very high or very low temperatures, you need to choose a material that can withstand these conditions.

For example, silicone can handle high temperatures, while EPDM is good for lower temperatures.

Chemical Compatibility

If the seal will be in contact with chemicals, oils, or other substances, you need to ensure the material can resist these chemicals.

Both gaskets and o-rings are available in different materials like nitrile, silicone, and EPDM.

Each material has its own resistance properties.

For example, nitrile is good for oil resistance, while EPDM is resistant to many chemicals.

Choose the material that is best suited for the chemicals your machine uses.

Ease of Installation and Maintenance

Consider how easy it is to install and replace the seal.

If you need a seal that is easy to install and replace, especially if you need to do it often, a rubber gasket is a good choice.

Gaskets are usually easier to handle, especially on flat surfaces.

You can cut them to size and fit them between parts quickly.

If the seal needs to fit into small or tight spaces, a rubber o-ring is more suitable.

O-rings are small and can fit into tight grooves.

Its features make it ideal for compact areas.

Size and Space Constraints

The available space for a seal influences the choice between rubber gaskets vs. rubber o-rings.

If the area that needs sealing is large or irregularly shaped, a rubber gasket is the better option.

Gaskets can cover larger areas and can be cut to fit any shape.

They offer flexibility in terms of size and shape coverage.

If the area that needs sealing is small or confined, a rubber o-ring is the right choice.

O-rings are small and can fit well into tight spaces, providing a reliable seal in areas where larger gaskets might not fit.

Conclusion

If you’re working with seals that don’t move or do, need to handle a lot of pressure, or have to deal with chemicals, picking the right one is really important.

Therefore, you need to know the difference between rubber gaskets vs. rubber o-rings to keep your machines working well.

And if you need help finding the best rubber seals for your machines, Rubber Xperts is here for you.

We have all kinds of rubber seals that we can make just for your needs.

Our products are top-notch and will help your machines run smoothly.

Need the right rubber seal?

Contact Rubber Xperts today!